Pumps are often touted for their high-capacity flow rates, and this is important in many applications such as bulk transfer, gland seal flushing and saltwater disposal.

For metering applications where precision and accuracy take precedence, just the opposite—low flow rates—are often required. Since it is metering, a pump should also meet the American Petroleum Institute (API) 675 standards for steady-state accuracy (plus or minus 1 percent), linearity (plus or minus 3 percent), and repeatability (plus or minus 3 percent). Low flows are required for many processing and manufacturing applications, including many in the water and wastewater industry. These can include mixing polymers for water treatment and dosing phosphates, ammonia and other chemicals in boiler feed; metering methanol or corn syrup for wastewater nitrification; and general chemical injection.

At least one triplex metering pump with a flow rate range of 0.06 gallons per hour (gph) to 8 gph while exceeding API 675 performance standards is available. This pump can deliver flows at discharge pressures up to 3,500 pounds per square inch (psi) for metallic pump heads and 350 psi for nonmetallic pump heads (depending on material).

Image 1. Wastewater aerial (Images courtesy of Wanner Engineering Inc.)

Image 1. Wastewater aerial (Images courtesy of Wanner Engineering Inc.)With three hydraulically actuated, balanced diaphragms, triplex metering pumps provide virtually pulse-free, linear flow without the need for expensive pulsation dampeners. Triplex metering pumps also offer a replenishment valve system that ensures continuous accuracy and protects the pump from damage in the event of a blocked suction line.

Two examples of how the triplex metering pump performed well are with polymer mixing for water treatment and injecting additives to natural fibers in the manufacture of construction materials.

At a water treatment facility in the southeastern United States, a plant manager needed a low-flow metering pump for a new installation to operate at a pressure rating of 1,800 psi. The idea of using a low-flow pump with reduced pulsations was attractive to him as it allowed for a linear injection stream as opposed to the slugs produced by traditional single diaphragm metering pumps. Two triplex metering pumps were installed, and they are operating without issue on intermittent duty cycles with flow rates ranging from 0.54 to 2.76 gph. The polymer has a viscosity of 1,200 centipoise (cP).

In Northern Europe, a manufacturer of plastic roofs and wall coverings sought a pump that could not only deliver low flow at reduced pulsations, but could also handle a sheer-sensitive fluid with suspended particles. The sealless design and low-shear pumping action enabled the pump to process suspended solids and protect the shear-sensitive additives. Three triplex metering pumps are running successfully on intermittent duty at flow rates from only 0.06 to 0.13 gph and discharge pressures from 29 to 232 psi.

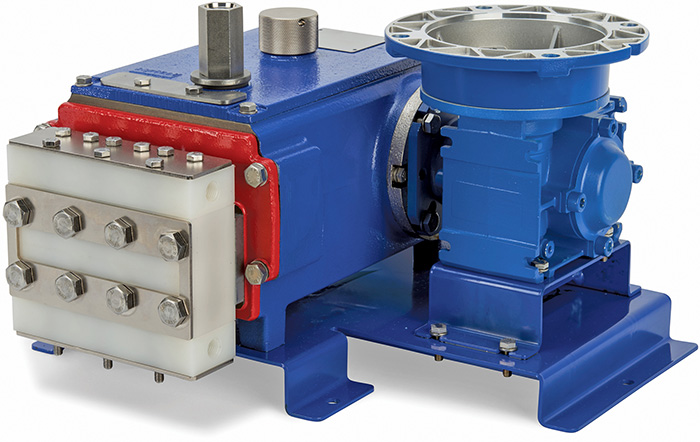

Image 2. Triplex metering pump

Image 2. Triplex metering pumpThe ability of the triplex metering pump to handle suspended solids also has advantages in boiler feed and water and wastewater treatment. One challenge with dosing boiler feed chemicals is in the handling of liquids with suspended solids. Phosphate and ammonia can crystalize or not dissolve completely if mixed manually. The sealless design and check valves of one triplex pump enable it to pump liquids with suspended solids, handling particles up to 200 microns in size.

The sealless design also plays a role for pumping hydrogen peroxide solutions (H₂O₂) as a pre-oxidant. H₂O₂ can react violently with other substances, so it needs 100 percent containment. This is achieved by the sealless pumping chamber of the triplex metering pump, which separates the liquid end from the hydraulic end and has no leak paths. An internal pressure relief valve is typically required for H₂O₂ as well. An integral relief valve protects the pump from over pressurization on the discharge side.

A further advantage is lower installation cost. Since it is virtually pulse-free, pulsation dampeners are not required.

Image 3. Metering control panel

Image 3. Metering control panelAnother consideration in water and wastewater treatment is that the pump can meter a wide range of processing fluids, including viscous liquids greater than 2,000 cP.

Boiler feed and the metering of H₂O₂ or urea require metallic pump heads to handle discharge pressures in the 1,500 to 3,000 psi range.

Lower pressure applications, such as wastewater nitrification and general chemical injection, can use nonmetallic pump heads.

The hydraulically balanced diaphragms allow the pump to provide consistent performance across the entire pressure range. In addition to low flow delivery in water and wastewater treatment, triplex metering pumps can be used for metering and dosing throughout the chemical processing industries, such as oil and gas (offshore and onshore), high-pressure process chromatography, pharmaceutical and personal care products manufacturing, injection of additives in the plastics industry, and several uses in the production of polyurethane foam.