The Sealing Sense column on expansion joints fundamentals in the January 2017 issue of Pumps & Systems (Read it here) concluded the five-part “Back to Basics” series presented by the Fluid Sealing Association (FSA). This month’s column focuses on a new technical resource that thoroughly explains the performance, design and variations of expansion joints.

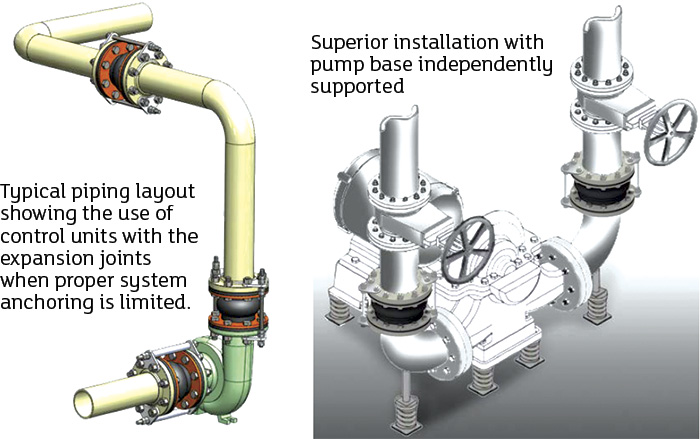

The Piping Expansion Joint Division recently completed revisions for the 8th edition of the Piping Handbook, now called the Piping Expansion Joints Technical Handbook. The revised handbook includes a contemporary format with new three-dimensional graphics (see Figure 1). The technical content has been expanded and revised to reflect a wider variety of expansion joints and to make the handbook more relevant to the user.

Figure 1. New graphics in the handbook to illustrate expansion joint usage (Graphics courtesy of the author)

Figure 1. New graphics in the handbook to illustrate expansion joint usage (Graphics courtesy of the author)The handbook provides up-to-date compilations of construction standards and guides for specifying and purchasing non-metallic expansion joints and flexible pipe connectors. It is based on the latest information concerning research, design and application of rubber (elastomer) expansion joints by engineers associated with the FSA’s Non-Metallic Expansion Joint Division member companies.

The publication is intended to be a reference for engineers who design and install piping systems.

This handbook is not intended to serve as a manual for design of piping systems. Its purpose is to provide guidance on design and selection of material and proper installation procedures. It has been widely used in customer inquiries as a reference for expansion joint design and performance standards.

The definitions section has been expanded to include more items relevant to the industry. The definitions are now consistent with the Ducting Expansion Joint Handbook and other publications.

Expansion Joint Types

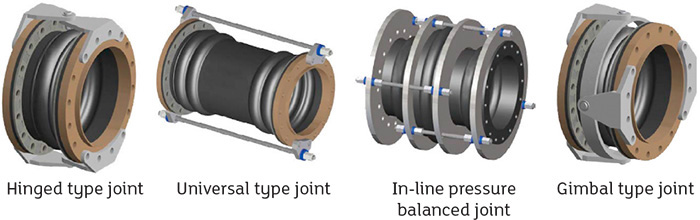

There are several types of expansion joints, and several variations of these joints are available. While previous versions of the handbook described the basic types of expansion joints, several common variations were missing. These are part of the 8th edition, which includes sections on hinged, universal, pressure-balanced and gimbal arrangements (see Figure 2).

Figure 2. Expansion joint types

Figure 2. Expansion joint typesThe Piping Expansion Joint Committee decided that these joints deserved a new chapter. Another common expansion joint, the molded spherical type, previously did not have a section.

- Hinged joints: Hinged type rubber expansion joints are designed to permit angular rotation in one plane. The arrangement consists of a pair of hinge plates connected with pins and attached to the expansion joints’ external or internal hardware.

- Universal joints: Universal type rubber expansion joints are designed to permit extension, compression, lateral and angular movements. The arrangement consists of two rubber expansion joints connected by a center spool with restraint hardware.

- Pressure balanced: Pressure balanced type rubber expansion joints are designed to absorb compression, as well as lateral and angular movements, while restraining the pressure thrust force. The arrangement consists of two or three rubber expansion joints and interconnecting hardware.

- Gimbal joints: Gimbal type rubber expansion joints are designed to permit angular rotation in multiple planes. The arrangement consists of two pairs of hinge plates connected with pins to a common gimbal ring and attached to the expansion joints’ external or internal hardware.

FSA Standards

Rubber expansion joints are not covered in any meaningful detail in any of the pipe codes or American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC). The FSA standards are the only comprehensive standards addressing rubber expansion joint specifications, performance assessment and use.

Three FSA standards have been included in the 8th edition:

- FSA-PSJ-701-06 Non-Metallic Expansion Joint Hydrotesting and Vacuum Testing: This standard covers the hydro testing and vacuum testing of non-metallic flanged expansion joints. The purpose of the testing is to verify that the expansion joint meets a standard performance or a customer-specified performance.

- FSA-PSJ-702-15 Rubber Flanged Non-Metallic Expansion Joint Installation, Maintenance, and Storage: This specification covers the installation, maintenance and storage of rubber flanged non-metallic expansion joints. The purpose of the standard is to ensure the proper handling of expansion joints. The bolt torque values listed in this standard were updated after review and verification.

- FSA-PSJ-703-11 Guidelines for Elastomers Used in Piping Systems Non-Metallic Piping Joints: This guideline provides the typical properties of elastomers most frequently used for tube and cover compounds in the manufacture of piping expansion joints for a wide range of applications.

The three standards are available as standalone documents; however, the authors of the Piping Expansion Joint Handbook decided to incorporate these standards to consolidate all information, and raise awareness of the standards.

The standards and the technical handbook are freely available from the FSA website: www.fluidsealing.com/expansion-joints/expansion-joints-publications/.

The committee’s goal of completing the revisions before the end of 2016 could not have been accomplished without extensive cooperation from all members in person and online.

The revised handbook is the result of the contributions of several committee members who dedicated many hours to the project.

The committee acknowledged Rob Coffee and Gary Eiseman for leading the project, and Henri Azibert for coordinating the meetings.

For more information about expansion joints, visit the FSA product locator at www.fluidsealing.com/product-locator, or contact a manufacturer.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.