More than 60 million tons of polyethylene are manufactured each year, making it the world's most pervasive plastic. It is used to make bottles, buckets, packaging and dozens of other products that we see and touch every day. The feedstocks used to make plastics are crude oil and natural gas, which are broken down into smaller components, such as naphtha, ethane and propane (among others). Larger hydrocarbons are further separated into smaller molecules through a complex cracking process that uses temperature, pressure and chemical additives to create the building blocks needed to transform feedstock into plastics.

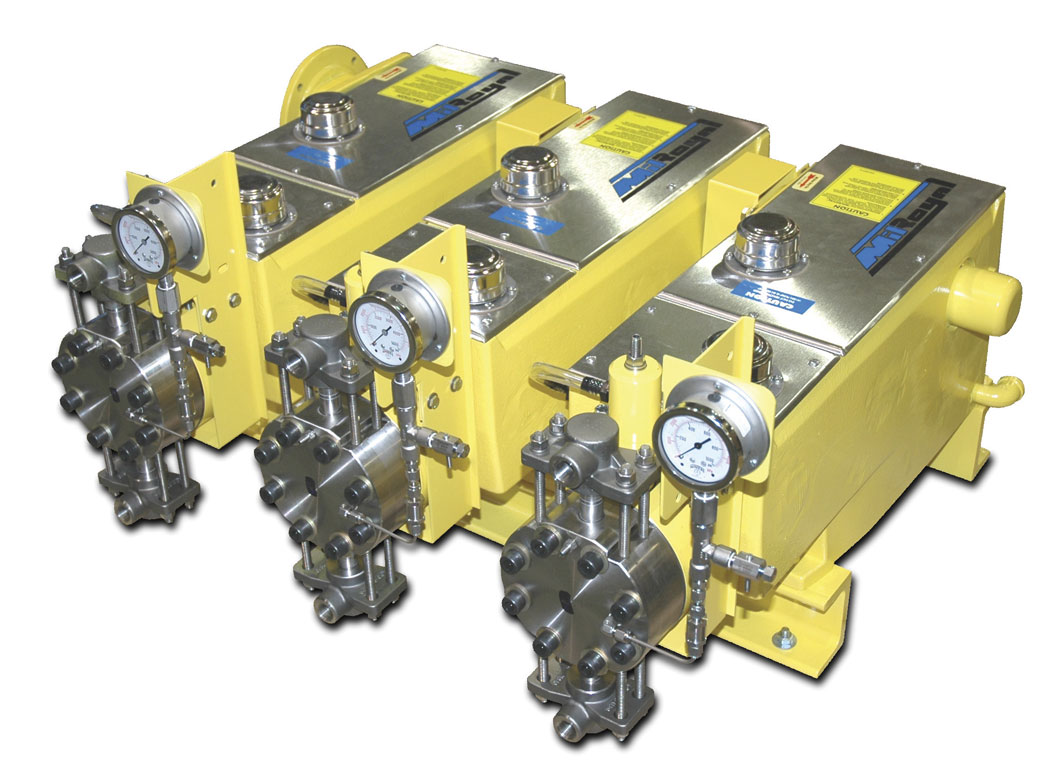

Image 1. These metering pumps are designed for high-pressure, critical chemical processing. (Images courtesy of Milton Roy)

Image 1. These metering pumps are designed for high-pressure, critical chemical processing. (Images courtesy of Milton Roy)Pump Accuracy

Although metering pump accuracy is important in any industry, it takes on a different meaning in critical chemical processing. As a comparison, consider metering pumps used for some other industries where small tolerances in the volume of chemicals rendered will still produce the desired effect. Consider the same scenario with metering chemical catalysts to make plastics. Hydrocarbons changing state do not pass from a single starting point to a single end point. Instead, they follow a dynamic continuum where pressure and temperature variations, or different volumes of catalysts, can cause feedstocks to transform into any number of elements. Metering out too much or too little can result in an explosion, or it can render a product that does not resemble the desired plastic. Either way, it is paramount to dose the precise amounts of catalysts at precisely the right time to produce the desired product. In chemical processing, accuracy goes beyond quality control. It also affects the bottom line. Because chemical plants run continuous operations, actions need to be done right the first time. It is difficult and, in some cases, impossible, to repeat the setup and start over. Errors in one part of the process create ripple effects elsewhere that cost time and money. For all of these reasons, metering pumps must be designed to deliver ±1 percent steady state accuracy with 100 to 1 turndown ratios and capacity that can be adjusted by manual controls, variable speed drives, and electronic or pneumatic actuators. Image 2. The hydraulically actuated diaphragm operates with equal pressure between the hydraulic and process fluids, resulting in low stress on the moving parts which leads to better pump performance and longevity.

Image 2. The hydraulically actuated diaphragm operates with equal pressure between the hydraulic and process fluids, resulting in low stress on the moving parts which leads to better pump performance and longevity.Increased Reliability

Failures or unscheduled maintenance activities can have expensive consequences for plants that run operations on a 24-hour basis. To guard against failures, many of the largest chemical processing companies rely on metering pumps with hydraulically actuated diaphragms (HAD). The secret to the HAD pump's longevity is a Teflon diaphragm that acts as a barrier between the piston and process fluids. The HAD operates with equal pressure between the hydraulic and process fluids, eliminating diaphragm stress, since the pressure is essentially equal on both sides at all times. Without equal pressure on both sides, the diaphragm would have to withstand all of the process pressure. With a HAD pump, the diaphragm is balanced and remains under low stress. None of the moving parts get stretched or compressed, resulting in longevity that can run for 96,000 hours (or 10 years of continuous uptime) with minimal maintenance.System Flexibility

Because of the toxic nature of fluids, combined with numerous temperature and pressure variations during production, flexibility in metering pump design is essential for process critical operations. Metering pump designs should be modular and customizable so that it can accept a variety of liquid ends (stainless, alloy, PVC) and meet different process requirements. Pumps should ideally have different frame sizes to be able to address a wide range of capacities and pressures. Multiplex configurations of the same frame or a mixture of frames creates even greater flexibility, allowing as many as 16 different pumps to be driven by one motor.Worker Safety

The harsh nature of the chemicals put through metering pumps can cause check valves and diaphragms to fail, causing clogs in the liquid end that lead to potential leaks. For applications up to 5,000 pounds per square inch (psi), a critical service diaphragm (CSD) has been engineered to handle high suction pressure. The CSD can handle suction pressures equal to the maximum discharge pressure of the pump without harming the diaphragm. This is particularly useful when handling saturated liquids, because suction pressure is needed to overcome high vapor pressures to keep the liquids in solution. In addition, CSD metering pumps assure high fluid velocity through the pump head. Front-scavenging technology on the diaphragm evacuates the entire liquid end with every stroke, cleaning it out and preventing clogs or leaks. Because some hydrocarbons ignite when they mix with air, metering pumps should not have any rotating seals that could cause leaks. They should have sealed diaphragms and, in some cases, double diaphragms with rupture detection systems that can shut down the pump's motor prior to any rupture.Conclusion

The production of plastics remains a huge industry, and it is one that continues to grow. Because of the rise in U.S. shale production, enhancing the ease of delivering feedstocks, more chemical processing plants have been built in the U.S. in the last two years than in the previous 15 years combined. The dangers associated with plastics production are well understood; the best practices for safely handling the materials are codified; and the technology that automates these best practices continues to evolve and improve. Given these factors, the long-term outlook for domestic polyethylene production is viable, and with MET metering pumps readily available, it truly is a time when chemical companies can have their cake and eat it, too.Case Study

The Challenge

Polypropylene reactor catalyst charge pumps used by a major polyethylene plant were experiencing numerous failures, leading to catalytic reactor unit shut downs and the loss of hundreds of thousands dollars of production per hour. The facility needed a more reliable pump that could withstand the harsh chemicals, pressures and processing conditions, and it needed a pump that could endure the climate fluctuations within the region.

The Solution

One manufacturer engineered a customized reactor charge pump. The pump featured critical service liquid ends, a specially designed diaphragm made from Gylon with thicker walls than standard pumps, and check valves equipped with hardened balls and seats. The pump\'92s design enabled it to accommodate the solids and viscosity encountered in the reactor fluid and pump the solids continuously to the catalyst reactor at about 800 psi with accuracy and reliability. In addition, the pump is unprotected from the weather, being exposed to conditions ranging from 100 F (38 C) heat to rain, wind and other harsh conditions. Because of the reliability of the pump's performance, the plant operator has installed pumps in other facilities within the region and across the globe.