Pumping Prescriptions

Pumping Machinery

10/03/2016

When a pump experiences internal wear, its performance drops. Flow is reduced and efficiency plummets. But what happens to power? Does it drop, stay the same or increase? The answer to this question depends on how a pump wears internally. In extreme cases, when the impeller is completely worn, there will be no flow and hardly any power. But in many cases, tight clearance parts, such as wear rings and bushings, are the first to wear.

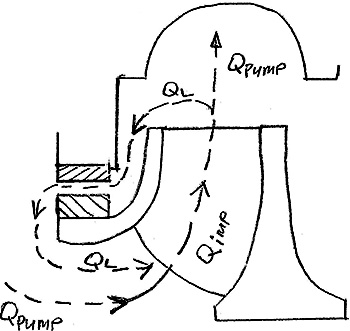

Figure 1. Parallel circuit: Flow through the impeller is greater than the actual pump discharge/suction flow by the amount of leakage. (Graphics courtesy of the author)

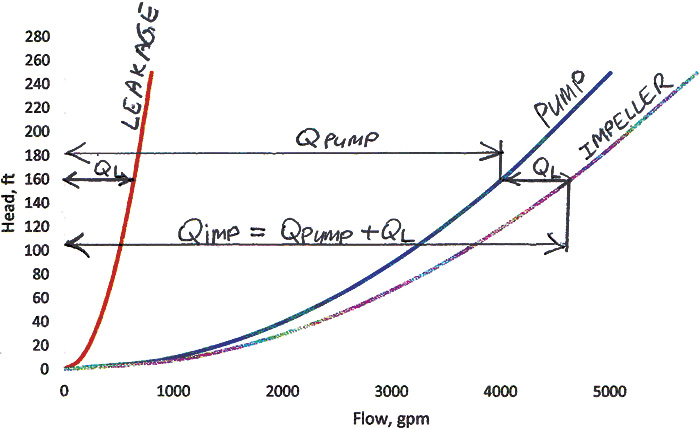

Figure 1. Parallel circuit: Flow through the impeller is greater than the actual pump discharge/suction flow by the amount of leakage. (Graphics courtesy of the author) Figure 2. Two systems in parallel. The pump flow joins with leakage recirculation to produce impeller flow.

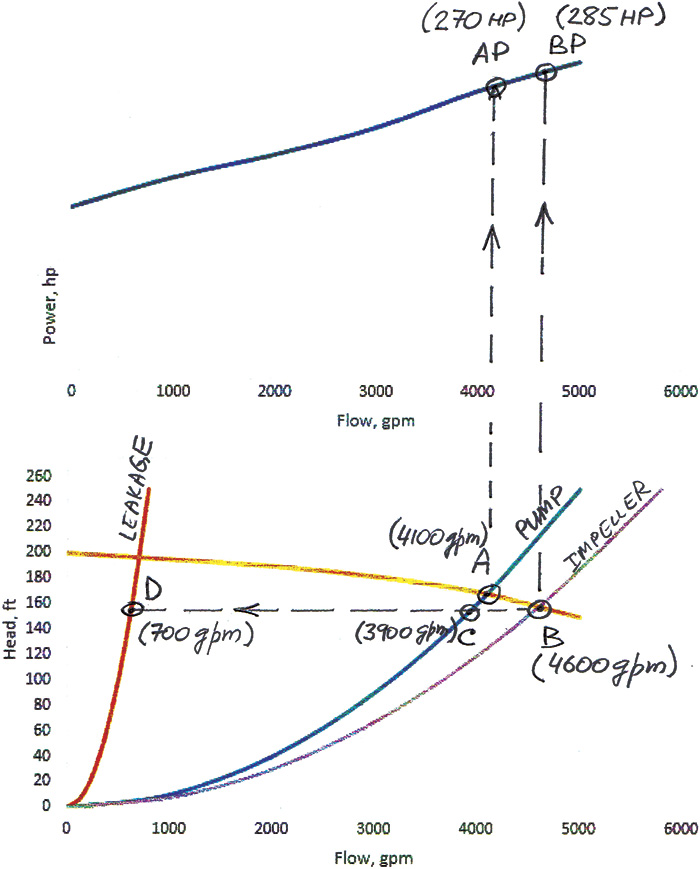

Figure 2. Two systems in parallel. The pump flow joins with leakage recirculation to produce impeller flow. Figure 3. Pump operating points

Figure 3. Pump operating points- System flow dropped.

- Pump power increased.

- Pump efficiency decreased.

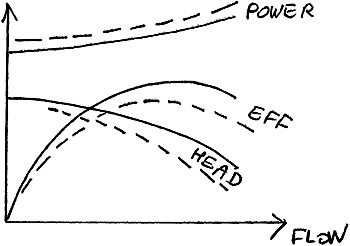

Figure 4. Change of performance with clearance (The solid line represents conditions before the clearance was opened, and the dashed line represents conditions after clearance was opened/worn.)

Figure 4. Change of performance with clearance (The solid line represents conditions before the clearance was opened, and the dashed line represents conditions after clearance was opened/worn.)

See other Pumping Prescriptions articles here.