01/22/2014

Q. What are some factors to consider when conducting a life-cycle cost evaluation for a sealless rotary pump? A. There is a substantial first-cost premium for sealless rotary pumps. Depending on the type, this cost is a multiple of a similar pump with a conventional mechanical seal. A magnetic drive pump’s expense is primarily associated with the cost of the magnets required to transmit torque. Sealless pumps may be selected for many applications based on a life-cycle cost analysis. Each application is subject to individual review, but general areas that may be considered in a life-cycle cost analysis are:

- Negative for sealless pumps

- Initial capital cost

- Additional instrumentation, if required

- Lower drive efficiency

- Variable cost elements based on user experience

- Cost of maintenance differential (numerous surveys have shown mechanical seal failure to be the primary cost of pump maintenance)

- Cost of production loss associated with system reliability

- Reduced cost of instrumentation compared to complex seal systems

- Positive for sealless pumps

- Monitoring exemption for fugitive emissions under the Clean Air Act

- Cost of liquid disposal as a result of seal failure

- Risk associated with personnel or fire incident loss

- Cost of alternate sealing systems to meet environmental emissions control requirements, such as double-seal and compliance

- Value of extended operating periods between unit turnaround

- Space reduction when compared to complex seal systems

- Cooling water costs

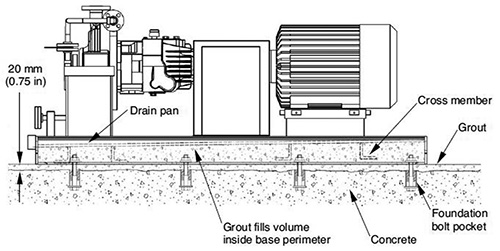

Figure 1.3.8.2.1a. Grouted baseplate, fabricated steel

Figure 1.3.8.2.1a. Grouted baseplate, fabricated steel Figure 1.3.8.2.2. Non-grout baseplate

Figure 1.3.8.2.2. Non-grout baseplate