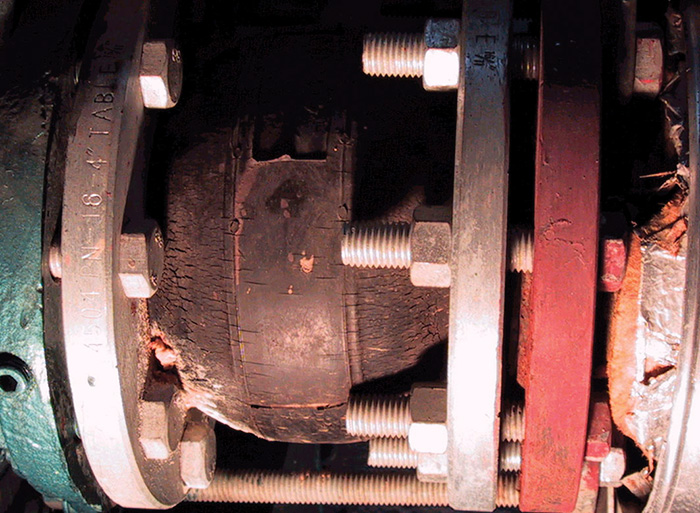

The practice of insulating over metallic expansion joints to minimize heat loss in a piping system may be common, but it is not a good idea to follow this same practice with rubber expansion joints. Rubber expansion joints typically consist of synthetic (oil-based) elastomers (ethylene propylene diene monomer [EPDM], neoprene, chlorobutyl, nitrile or clorosulphonated polyethlyene-CSM) combined with polyester or nylon and wire reinforcing that provide pressure-restraining capability. If an end user were to install a typical rubber expansion joint in a system needing insulation to cover the joint in a "hot" application, that individual must consider the probability of failure resulting from heat exposure. A rubber expansion joint that is covered by insulation will soak up heat from the fluids being pumped. When operating near the temperature limit of its constituent material, the rubber expansion joint may begin to lose its oil-based properties, drying out and causing the elastomers to become brittle.

Figure 1. Damaged elastomer expansion joint from excessive temperature (Images courtesy of FSA)

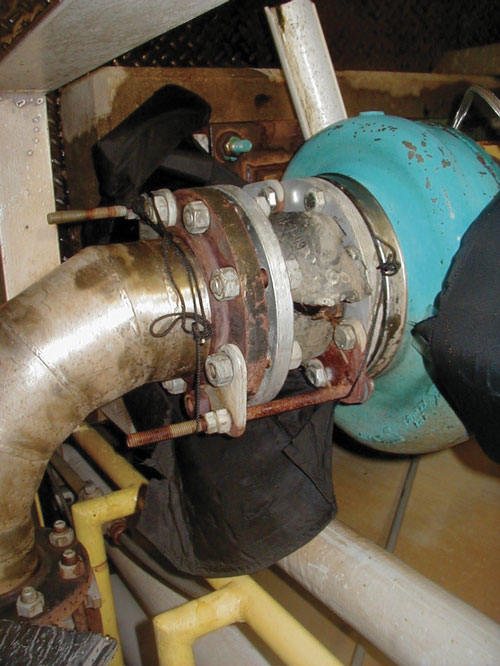

Figure 1. Damaged elastomer expansion joint from excessive temperature (Images courtesy of FSA) Figure 2. Insulated joint failure

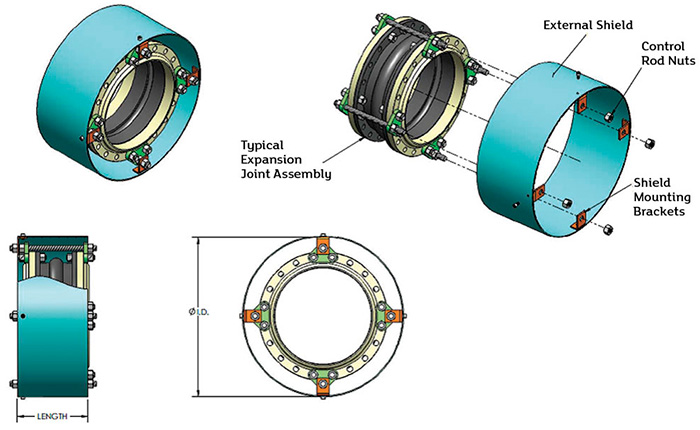

Figure 2. Insulated joint failure Figure 3. Metal cover option

Figure 3. Metal cover option