It is possible to significantly reduce the risk of carbon-graphite blistering.

Mechanical Seals

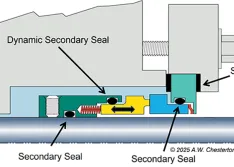

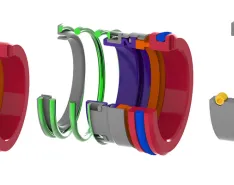

A guide to the function, types and materials of secondary sealing elements.

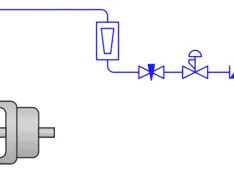

Why these systems are essential for equipment longevity and efficiency.

Best practices to avoid damaging the process pump or the seal.

What are the most common mechanical seal face materials?

Exploring potential challenges in industrial applications.

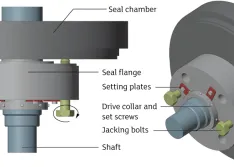

Exploring the fundamental components of mechanical seals and comparing different seal types.

Selecting and maintaining the proper seal for the operating environment.

A look at the past and potential future of mechanical seals.