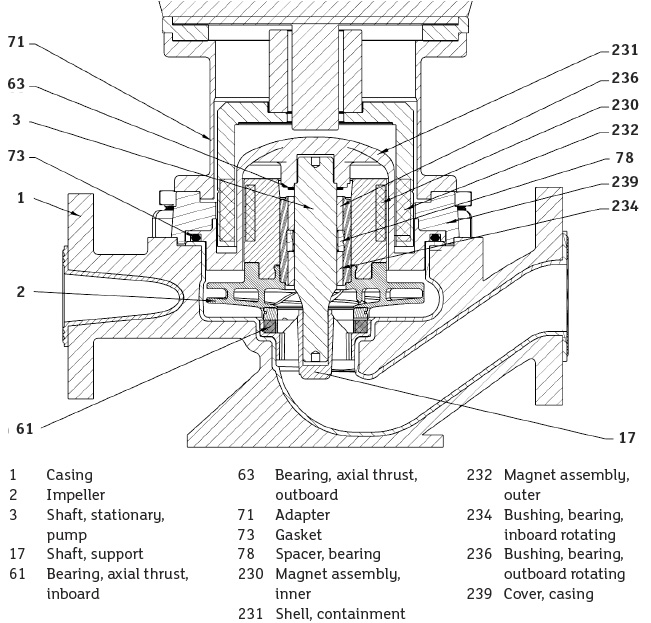

The HI Pump FAQs published in the October 2016 issue of Pump & Systems addressed a question related to secondary containment considerations for canned motor pumps and a separate question related to design considerations for magnetic-driven pumps (read that article here). Following that publication, it was requested that HI answer the same questions but for the opposing technology. Those questions and responses are presented in this month’s column. Q. What primary and secondary containment considerations are recommended for magnetic-driven pumps? A. The principal design consideration for sealless pumps is to prevent leakage to the atmosphere. A magnetic drive pump (MDP) (see Figure 1) is a type of sealless pump that uses an outer ring of permanent magnets to drive an internal rotating assembly through a corrosion-resistant containment shell. The torque transmission by a magnetic coupling eliminates the need for a traditional shaft seal.

Figure 1. Magnetic-driven pump (Graphics courtesy of Hydraulic Institute)

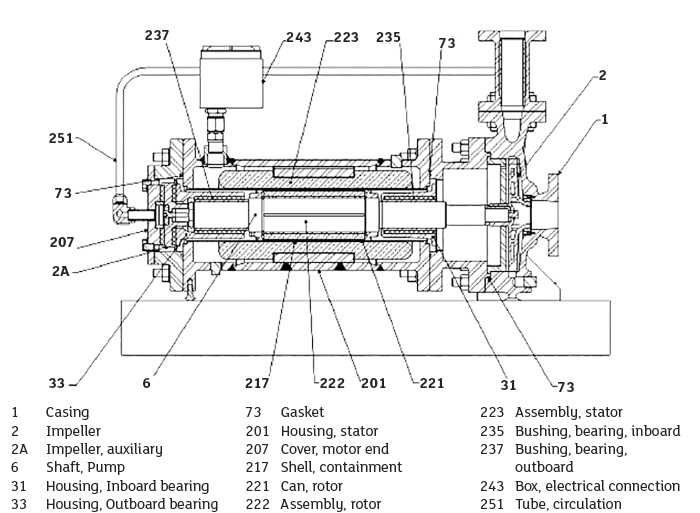

Figure 1. Magnetic-driven pump (Graphics courtesy of Hydraulic Institute) Figure 2. Canned motor pump

Figure 2. Canned motor pump