03/02/2016

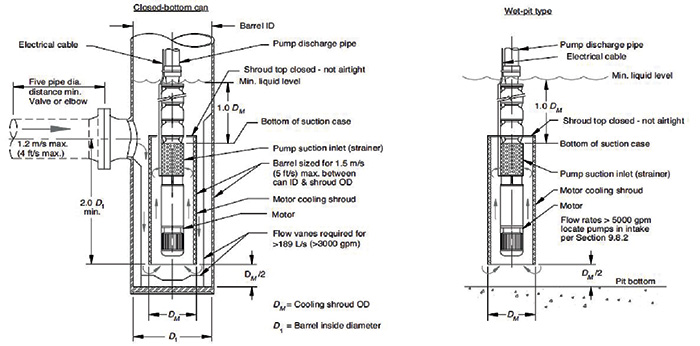

Q. What intake design considerations are important for submersible vertical turbine pumps? A. Submersible vertical turbine pumps can be installed in a wet pit or closed bottom can as shown in Figure G.1. Well motor types are recommended for both wet-pit type and closed-bottom can type of below-grade suction intakes in a rotodynamic pump.

Figure G.1. Submersible vertical turbine pump (Courtesy of Hydraulic Institute)

Figure G.1. Submersible vertical turbine pump (Courtesy of Hydraulic Institute)- the orientation of the structure relative to the body of supply liquid

- whether the structure is recessed from, flush with or protrudes beyond the boundaries of the body of supply liquid

- strength of currents in the body of supply liquid perpendicular to the direction of approach to the pumps

- the number of pumps required and their anticipated operating combinations

See other HI Pump FAQs articles here.