12/05/2014

Last year, “Reduce Thrust and Extend Bearing Life” (Pumps & Systems, December 2013) discussed the benefits and some potential pitfalls of adjusting the axial clearance of American National Standards Institute (ANSI) end-suction pumps. Adjusting the front clearance can help restore efficiency. As the front clearance wears, more leakage occurs. More energy is needed to drive leakage across the increased gap, raising operating costs. If the rotor position can be easily adjusted, the impeller front clearance is reduced, minimizing leakage and energy waste. However, a smart budget manager should ask these three questions before making adjustments.

1. How much energy is really saved?

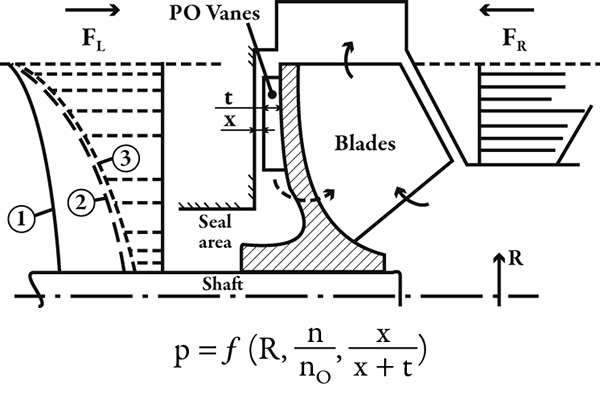

Saved energy depends on the size of the pump and how much pump efficiency has degraded. Several years ago in “How Much Energy is Wasted When Wear Rings Are Worn to Double Their Value?” (Pumps & Systems, March 2007), we calculated that a large pump—30-inch double-suction impeller, 1,000-horsepower (HP) motor—would waste about $24,000 per year at nonstop operation because of doubled clearance. A typical ANSI pump is much smaller (with rare exceptions), and a 25-HP motor is probably the maximum for the majority of ANSI applications. Divide the two horsepower values and multiply by the annual savings, and the resulting savings is about $600 per year. Figure 1. Axial thrust reduction using POVs (Courtesy of the author)

Figure 1. Axial thrust reduction using POVs (Courtesy of the author)