The accident resulted in over 3,500 barrels of oil being spilled.

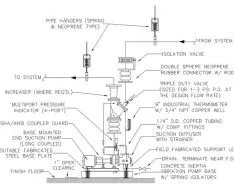

Piping

Grappling with aging infrastructure, a chronic skills shortage and a growing population, U.S. water utilities are currently facing a significant challenge.

Prevent costly failures by combating cavitation head on.

Answers to common questions about pipeline maintenance and ultrasonic inspection in refineries and chemical facilities.

Epoxy-based coatings can help materials work with many applications.

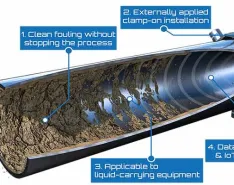

The power ultrasound solution can prevent fouling and scaling issues without using environmentally harmful chemicals—helping industries achieve environmental targets.

This practice can ensure safety and reliability of piping systems.

Learn how this alternative to metallics can boost your system.

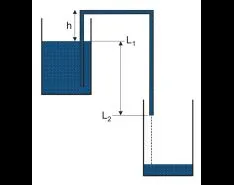

Using Bernoulli's equation to calculate what will happen in a piping system.

X-ray fluorescent tools can help identify materials and spot wear, while other testing can find corrosion’s root cause.

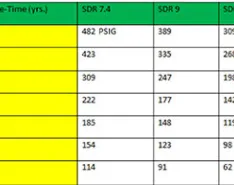

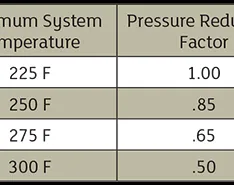

Consider chemicals, temperature, pressure, expansion and more.

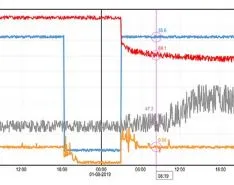

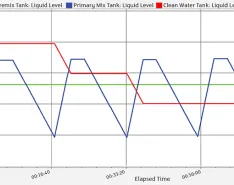

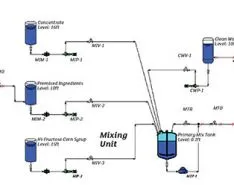

Case studies show how detecting leaks saves resources from going down the drain.

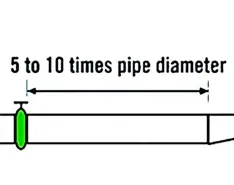

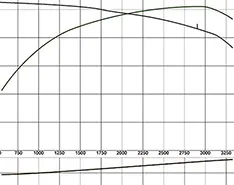

Size will have a major impact on all essential parameters.

Increase mechanical seal reliability with real-time knowledge.

Ray Hardee continues his explanation of process safety management.

Use piping system software to keep facilities safe.

Why rubber is the best choice for reducing problems.

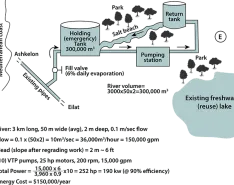

Choosing fresh water or salt water for a man-made river

By sizing the pipeline correctly, you can reduce both operating costs and the time the pump needs to operate.

The siphon is an example of a natural and extremely simple machine that we take advantage of daily.

A conservative approach was taken in choosing technologies for pumping abrasive slurries over long distances.