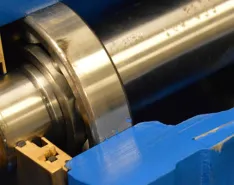

How intelligent lubrication can help manage bearing health in critical pump applications.

Bearings

Bearings are small parts of pump systems that play a critical role. They bear the load of the pump, allowing rotation. They must be properly lubricated and temperatures monitored to prevent failure. These articles explain the causes of bearing failure and how to prevent them - thus protecting overall system life.

Identifying key causes of bearing failures and effective preventive measures.

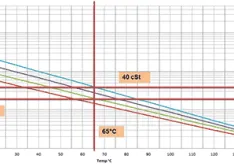

The importance of Kappa and fluid cleanliness to bearing life.

Highlighting the ways in which bearing life can be extended.

The variety of bearing isolators makes them suitable for many situations.

Two types of technology function best in challenging sealing environments.

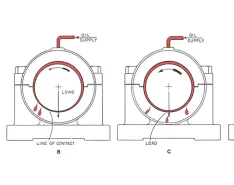

Understanding lubrication delivery methods and their applications.

Design, oil viscosity, clearance and functionality are important for proper function.

Proper procedures now can prevent problems later.