How advanced seal technology is protecting critical infrastructure in the energy transition.

Seals

Sealing solutions are critical to pumping to prevent leakage and, ultimately, failure. These are especially important in harsh conditions, whether from particulates, extreme temperature, or corrosive or heavily viscous fluid. The selection of the right seal can have as much impact on the system success as pump selection. These articles help with that selection and with the monitoring and maintaining of all types of seals.

The best solution may not be the most common.

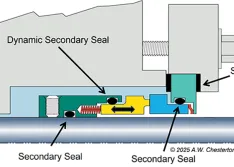

A guide to the function, types and materials of secondary sealing elements.

How sealing technology can help build a more sustainable future.

Pressure is an important factor influencing the closing force between the seal faces, and the seal design may need to be adjusted to accommodate higher pressures.

Reducing repair needs while meeting environmental goals.

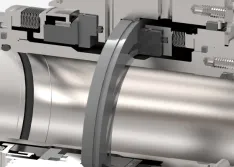

An in-depth look at gas seals and their functions.

How seals impact pump reliability and performance.

Exploring potential challenges in industrial applications.

Understanding how to best ensure optimal oil seal performance.

How to address jumping pipes without causing further damage.

Selecting and maintaining the proper seal for the operating environment.

Selecting and maintaining the proper seal for the operating environment.

What to consider when selecting the proper rubber expansion joint.

A look at the past and potential future of mechanical seals.

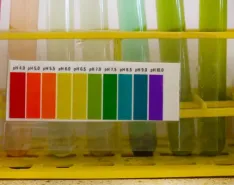

Both quality and safety are highly impacted by pH levels.

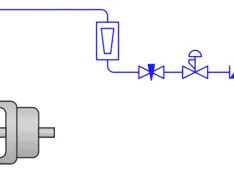

Curbing water consumption and emissions with mechanical seal technologies.

Material, temperature and pressure are important considerations when choosing a seal.

Using the right seal is critical in maintaining safe and efficient operations.

The importance of NSF/ANSI-61 certified expansion joints in potable water systems.

Timely replacement of compression packing is critical in avoiding downtime.