Best practices to avoid damaging the process pump or the seal.

Mechanical Seals

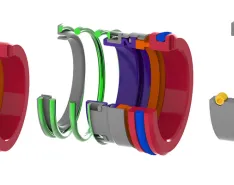

What are the most common mechanical seal face materials?

Exploring the fundamental components of mechanical seals and comparing different seal types.

Mechanical seals and gland packing are two common sealing devices used.

Hydropad technology lowers face operating temperatures and improves efficiency.

Adam Slade of John Crane joins the podcast to give the lowdown on NSF 61.

Finding the right seal depends on the equipment and application.

There are important factors and regulations to consider when choosing to repair rather than replace a mechanical seal

Optimize material and surface treatment selection.

Necessary precautions can lead to more success with the seal and systems.

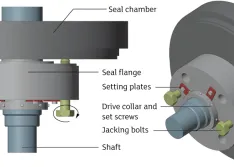

Making use of dual-stage mechanical seal systems.

The potential for energy savings and water use ratio (WUR) reduction can be identified swiftly if focus is placed on pump components such as mechanical seals.

Tips for selecting seal face materials in harsh conditions.

A liquid-lubricated seal may have no visible leakage.

Follow these tips to find cost-effective, reliable tools.

Reduce heat and wear with this unconventional balancing method.

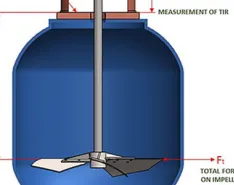

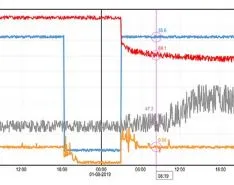

Increase mechanical seal reliability with real-time knowledge.

Problematic tasks can require improved performance in extreme operating conditions.

Rigorous temperature, pressure and exposure conditions must be met.

Predictive maintenance programs can increase the longevity of wear parts.