Necessary precautions can lead to more success with the seal and systems.

Mechanical Seals

Making use of dual-stage mechanical seal systems.

The potential for energy savings and water use ratio (WUR) reduction can be identified swiftly if focus is placed on pump components such as mechanical seals.

Tips for selecting seal face materials in harsh conditions.

A liquid-lubricated seal may have no visible leakage.

Follow these tips to find cost-effective, reliable tools.

Reduce heat and wear with this unconventional balancing method.

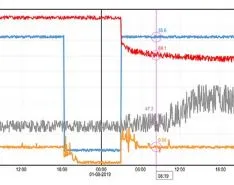

Increase mechanical seal reliability with real-time knowledge.

Problematic tasks can require improved performance in extreme operating conditions.