HI Pump FAQs

Hydraulic Institute

03/06/2018

What is the BEP, and what happens to a pumping system when a pump is not operated at the BEP?

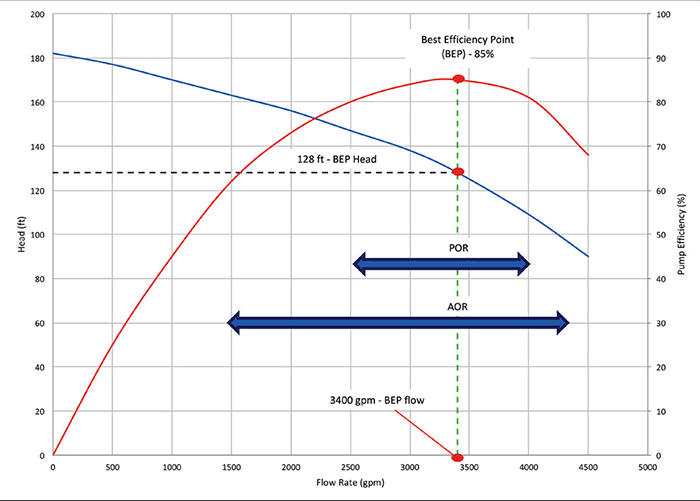

A: The BEP, or best efficiency point, is the point at which the pump operates at peak efficiency. At the BEP, flow enters and leaves the pump with a minimum amount of flow separation, turbulence, and other losses. The closer a pump operates to its BEP, the less wear the pump will experience, which increases the reliability of the pump. In the below image, the BEP is located at the apex of the pump efficiency curve (green line). If a vertical line is drawn from the BEP down to the pump curve (black line), the head and flow rate at the BEP can be determined by looking at where this line is in relation to horizontal and vertical axes. A closely related topic to the BEP is the preferred operating region, or POR. The POR is a range of rates of flow to either side of predicted BEP within which the hydraulic efficiency and the operational reliability of the pump are not substantially degraded. Within this region, the design service life of the pump will not be affected by the internal hydraulic loads or flow-induced vibration. Operating a pump within the POR ensures higher reliability and lower energy consumption. A typical range for the POR is shown on in Image 1. Note that the POR is defined in ANSI/HI 9.6.3 Rotodynamic Pumps Guideline for Operating Regions, and the POR changes depending if the pump radial (centrifugal), mixed or axial flow type. A wider range of flows, outside the POR, over which the service life of a pump is acceptable, is called the allowable operating region (AOR). The limits to AOR are determined by requirements other than energy consumption and should defined with the help of the pump manufacturer. Some factors that determine the AOR are:- hydraulic loads (bearing life, fatigue, mechanical contact, shaft deflection, thrust, etc.)

- liquid temperature rise

- bearing housing or shaft vibration

- audible noise

- power limitations

- net positive suction head

- suction recirculation

Image 1. BEP illustrated on head capacity curve with corresponding POR and AOR (Images courtesy of the Hydraulic Institute)

Image 1. BEP illustrated on head capacity curve with corresponding POR and AOR (Images courtesy of the Hydraulic Institute)Q: What is the difference between inside-mounted and outside-mounted mechanical seals?

A: Two categories of single mechanical seals are (1) inside-mounted and (2) outside-mounted. The primary difference between the two styles is that inside mounted seals are contained within the equipment seal chamber and outside-mounted seals are mounted external of the equipment housing. See Images 2 and 3 for diagrams of an inside-mounted and outside-mounted single seal. Inside-mounted mechanical seals : Image 2. Inside mounted seal

Image 2. Inside mounted seal- are available in a wide variety of materials and designs

- have centrifugal forces that tend to reduce leakage

- usually avoid catastrophic leakage during seal failure

Image 3. Outside mounted seal

Image 3. Outside mounted seal- typically easier to install

- adjustable without complete equipment disassembly

- accessible—can often be backed-off for cleaning

- usually less expensive

See other HI Pump FAQs articles here.