In 2012, I wrote a six-part series on centrifugal pump efficiency. In Part Five, I touched on the importance of the breadth of efficiency and how it can be more useful than the peak best efficiency point (BEP). During the past year, I have received a number of requests to revisit this topic and show some examples. I hope that this column will answer your questions.

Definition & Importance

I define breadth of efficiency as the range of flow at BEP and within a couple percentage points on either side of the BEP. This range is important for two reasons. Let me address the first one with a question. How often does a pump, running at full speed, operate at its BEP? The answer is seldom. Simple systems will often operate at BEP. However, more complex systems—upgrades to existing systems with older pipe and “build/design” systems—usually do not. The second reason is that a wide efficiency range will allow higher operating efficiency when pump speed is reduced by a variable frequency drive (VFD). Peak BEP efficiency is also important, but losing one or two points to attain a wider range of efficiency can be a reasonable trade off. As a rule of thumb, higher flow pumps usually have broader BEP ranges than lower flow pumps. However, some low-flow designs offer a much broader range of efficiency than do others. Sometimes, one manufacturer’s pump will have a broader range than those of its competitors. In other cases, a single manufacturer will have several different models that produce similar flows at different efficiency ranges.

Examples

Let’s take a look at two lower flow pumps with different efficiency ranges. These are real pumps, and I downloaded the pump curves from the manufacturer’s electronic catalogs. Figure 1 shows the variable speed curves for a 3x4x13, end-suction pump (Pump A) operating against an ideal system curve that intersects the center of the BEP range at 60 hertz. The red dots show the BEP range. The BEP remains at 75 percent from approximately 465 gallons per minute (gpm) to 530 gpm (a 65-gpm range). At full speed, the efficiency drops to about 68 percent at 400 gpm.

Figure 1. The variable speed curves for a 3x4x13, end-suction pump (Pump A)

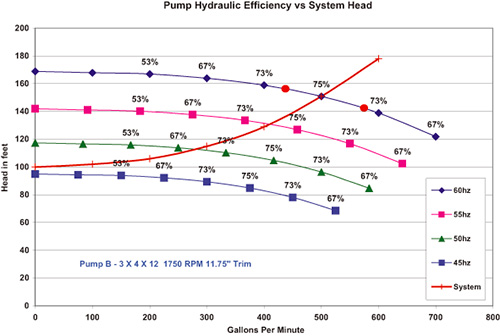

Figure 1. The variable speed curves for a 3x4x13, end-suction pump (Pump A)Under VFD control, the efficiency drops to about 71 percent at 400 gpm (approximately 54 hertz), and at 300 gpm (50 hertz), the efficiency drops to 65 percent. In a variable speed application, designed for flows from 250 to 500 gpm, pump efficiency will range from 60 percent to 75 percent. Figure 2 shows the performance curve for a 3x4x12, end-suction pump (Pump B) plotted against the same system curve. The BEP efficiency is also 75 percent, but the range is more than twice that of the example in Figure 1—425 gpm to 575 gpm (a 150-gpm range). Full speed efficiency drops just 2 points at 400 gpm and just 1 point when under VFD control. At 300 gpm, variable speed efficiency remains at 71 percent. In a variable speed application designed for the same range of flow as the example in Figure 1 (250 to 500 gpm), Pump B’s efficiency ranges from 68 percent to 75 percent.

Figure 2. The performance curve for a 3x4x12, end-suction pump (Pump B)

Figure 2. The performance curve for a 3x4x12, end-suction pump (Pump B)Pump B would be the best choice for both across the line (full speed) and variable speed operation. Its increased breadth of efficiency provides a better chance of actually hitting the BEP when operating at full speed. It will also offer an overall higher efficiency when operating at variable speed. If you look at pumps across the industry, you will find many examples in which this holds true—especially with lower flow pumps. We have many choices when selecting pumps. Take your time and compare several models and manufacturers.