In late 2023, the Valves & Fittings working group at 3-A Sanitary Standards, Inc. (SSI) introduced a significant update to its hygienic standard for ball valves. The new standard, 68-01, clarified a key issue: While ball valves were historically cleaned by clean-in-place (CIP) systems, they are not actually CIP-capable. According to the updated standard, ball valves are repeatedly called out as clean-out-of-place (COP) only (A1, E4.1, F7.1). This change has far-reaching implications for food processing plants, as it forces a reassessment of the role of ball valves in systems where CIP cleaning has been the norm.

This article will explore the impact of the 68-01 update, how it affects different sectors of the food processing industry and why it may be time to consider more hygienic alternatives.

The 68-01 Update & Its Impact

Before the 68-01 update, many food processing plants utilized ball valves as part of their process lines, with the understanding that they could be cleaned in place using CIP systems. CIP cleaning offers the advantage of cleaning equipment without disassembly, providing a timesaving, efficient way to maintain hygienic standards.

However, the new 68-01 standard clarifies that ball valves do not meet the stringent requirements for CIP systems and are instead suitable only for COP cleaning. COP requires daily, manual disassembly of components for thorough cleaning, which is more labor-intensive and results in greater operational downtime. The update further states that any ball valve not marked as “COP only” is no longer eligible to carry a 3-A certification (F7.1). For food processing plants that have historically relied on CIP cleaning for ball valves, this is a significant regulatory shift.

Regulatory Context for Various Food Processing Plants

The impact of the 68-01 update extends across multiple segments of the food processing industry, including dairy, beverage and pharmaceutical plants. The reliance on CIP systems in these sectors is well-established, as CIP allows for faster and more reliable cleaning processes without requiring equipment to be taken offline. However, with the updated classification of ball valves as COP-only, plants using ball valves in their CIP systems are now at risk of falling out of compliance with 3-A standards.

Failure to adhere to these updated standards could result in fines, product recalls and other regulatory repercussions. Moreover, from a hygiene and safety standpoint, the continued use of ball valves in processes where CIP cleaning is required exposes plants to contamination risks that could have serious consequences for consumer safety.

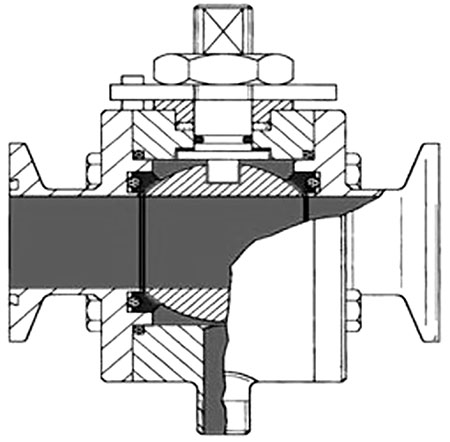

Ball Valves: Why They Are Not CIP-Compatible

The limitations of ball valves in CIP systems stem from their design, which was never optimized for the rigors of hygienic processing environments. While ball valves may have been used in CIP systems in the past, their shortcomings have now been formally recognized. Key issues include:

- Dead spaces: The design of ball valves creates dead spaces where product can become trapped, leading to contamination risks.

- Blockage and pinch risk: Ball valves can be prone to product inclusion and blockage due to their construction, which can disrupt the flow of material.

- Pigging process failure: In applications that use pigging systems to clean pipelines, the 0-degree open position of a ball valve interferes with pigging operations, leading to system failures, especially with static pigs.

- High maintenance demands: Ball valves must be fully removed from the process line for maintenance and cleaning. This process is labor-intensive and results in costly production downtimes.

- Leak potential: Ball valves have more components and wear parts, increasing the likelihood of leaks, especially at low pressures.

- Unhygienic design: Perhaps most critically, ball valves cannot meet the hygienic design standards required for CIP systems. Their design does not allow for effective cleaning without disassembly.

These limitations demonstrate why ball valves have been reclassified as COP-only and why they are no longer considered suitable for use in CIP systems.

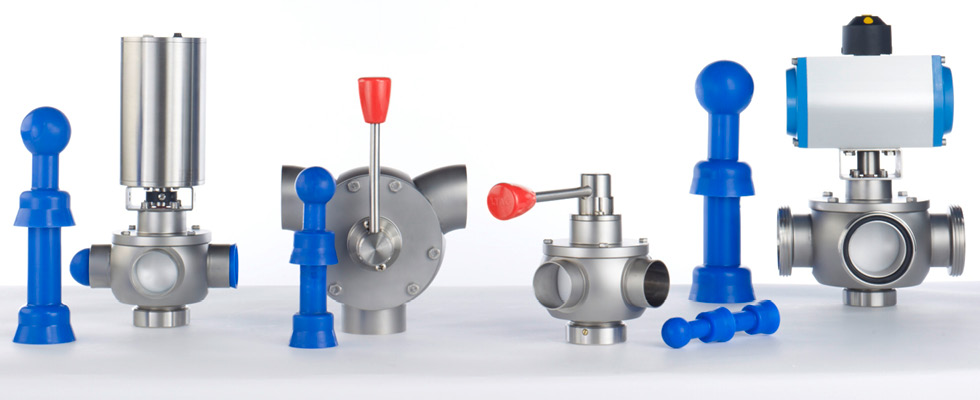

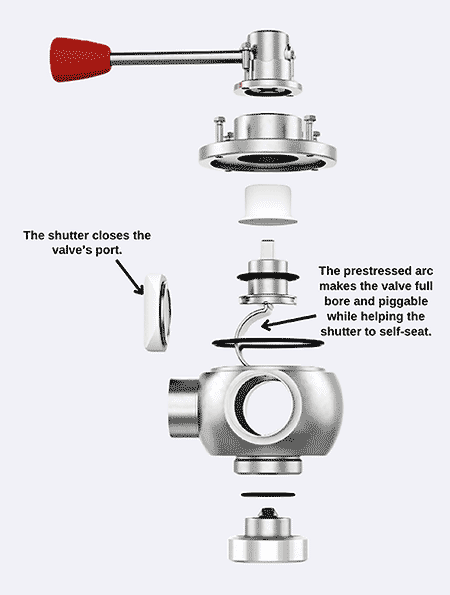

Arc/Shutter Valves: A More Hygienic Alternative

With the limitations of ball valves now formally recognized, arc/shutter valves provide a hygienic and versatile alternative. Unlike ball valves, arc/shutter valves are designed specifically for use in CIP systems and address many of the hygiene and maintenance challenges ball valves cannot overcome. Some of the benefits of arc/shutter valves include:

- No dead space: The design of arc/shutter valves eliminates dead spaces, drastically reducing the risk of product contamination.

- No blockage or pinching: Arc/shutter valves ensure smooth product flow without the risk of blockage or pinching.

- Improved pigging performance: Unlike ball valves, arc/shutter valves’ exact 0-degree position does not interfere with pigging operations.

- Simplified maintenance: Even when welded into the line, arc/shutter valves can be fully dismantled for cleaning and maintenance without the need for complete removal, minimizing downtime.

- Fewer components, less wear: Arc/shutter valves feature fewer components and wear parts compared to ball valves, reducing the potential for leaks and failures.

- Hygienic CIP design: Arc/shutter valves are fully CIP-compatible, offering a hygienic design that can be cleaned in place without the need for disassembly.

By offering these advanced features, arc/shutter valves not only meet but exceed the standards required for CIP systems in modern food processing environments.

Long-Term Benefits of Switching to Arc/Shutter Valves

Upgrading from ball valves to arc/shutter valves offers significant long-term benefits for food processing plants. In addition to ensuring compliance with the latest 3-A standards, arc/shutter valves provide a higher level of reliability, reduced downtime and fewer maintenance interruptions.

Their simplified design, combined with their ability to be cleaned in place, means arc/shutter valves will save time and money over the life span of the system. Furthermore, arc/shutter valves offer a more sustainable, hygienic solution that aligns with evolving industry standards and regulatory requirements.

The 68-01 update from 3-A SSI marks a turning point for food processing plants that have historically relied on ball valves in CIP systems. With ball valves now recognized as COP-only, plant managers must reassess their equipment and make necessary upgrades to ensure compliance with the latest hygienic standards.

References

- 3-A SSI. (2023 September). 3-A SSI Releases Revised Sanitary Standard for Ball-Type Valves, Number 68-01. 3-a.org/legacy-newsletters/3-a-ssi-releases-revised-sanitary-standard-for-ball-type-valves-number-68-01

- 3-A SSI, “3-A Sanitary Standard for Ball-Type Valves, Number 68-01”, September 2023