A wastewater treatment plant is designed to protect the community it serves. However, if the complex process of removing harmful substances from wastewater is not carefully managed, the plant may not be able to fulfill its purpose. Monitoring the flow of influent (incoming domestic, commercial or industrial wastewater) and effluent (treated water that is discharged or repurposed) is crucial for remaining in compliance with increasingly strict legislation that holds treatment facilities accountable for their impact on public and environmental health. Several flow technologies can measure wastewater as it advances through the treatment process, but clamp-on ultrasonic flow offers a combination of benefits that should not be overlooked. A properly outfitted clamp-on flow meter is suitable for most wastewater applications. It performs more accurately than a traditional mechanical meter and is often more cost-effective than an electromagnetic or inline ultrasonic meter.

Different Methods of Measurement

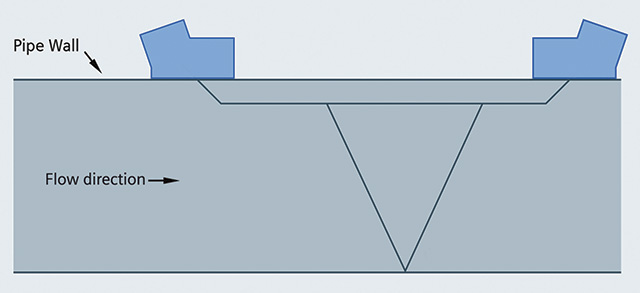

A clamp-on ultrasonic flow meter consists of at least two sensors mounted externally to a pipe. The sensors measure flow by transmitting and receiving ultrasonic signals directly through the pipe wall and the medium, but the method in which the flow rate is determined varies depending on the nature of the application. Transit-time measurement calculates the difference in arrival time between sound waves traveling in the same direction as flow and those traveling against it (see Figure 1). This difference is directly proportional to the mean flow velocity of the medium. Transit-time is the preferred mode of operation for relatively homogeneous liquids and is highly accurate—generally up to 0.5 percent of flow. Figure 1. Transit-time measurement (Graphics courtesy of Siemens Process Industries and Drives)

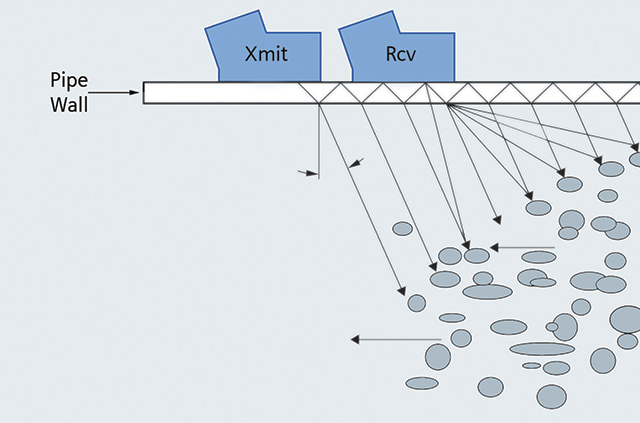

Figure 1. Transit-time measurement (Graphics courtesy of Siemens Process Industries and Drives) Figure 2. Doppler measurement

Figure 2. Doppler measurementAccurate and Versatile Transit-Time

Clamp-on flow technology is sometimes perceived as a poor choice for wastewater treatment applications because of the misconception that transit-time meters can only measure liquids devoid of any particles or bubbles, leaving lower-accuracy Doppler meters as the sole clamp-on option for most wastewater applications. In reality, a high-quality transit-time meter is capable of tolerating a sizeable amount of solids without any compromise in performance. The maximum concentration depends on which type of sensor is used:- Shear mode or narrow beam. A transmitting shear mode sensor injects an acoustic signal into the pipe wall, through the flowing liquid and directly into the receiving sensor. When fitted with shear mode sensors, a transit-time meter will generally retain its accuracy level with a total solids content of up to 7 percent.

- Lamb wave or wide beam. Lamb wave sensors operate by broadcasting a variety of frequencies through the pipe to determine which most closely resembles the pipe wall. The matching frequency is then transmitted into the liquid with the pipe wall serving as a waveguide, allowing a broader swath of ultrasonic energy to cross the pipe and increasing the probability of a strong signal during times of high particle content. The wider beam produced by this method results in a solids tolerance of up to 15 percent.

- raw sewage

- primary sludge

- return- and waste-activated sludge (RAS and WAS)

- mixed liquor

- chemical additives

- effluent

Lower Cost of Ownership

With the costs of wastewater treatment and disposal rising annually in response to more stringent governmental regulation, investing in the right flow instrumentation is one of the most cost-effective business decisions a wastewater treatment plant can make. Clamp-on meters offer an overall lower cost of ownership because they can operate under a wide range of operating conditions and due to their externally oriented sensors and lack of moving parts. Installation of a mechanical, electromagnetic or inline ultrasonic flow meter requires shutting down the process and cutting into the pipe, potentially resulting in lost productivity and revenue. This is not the case for clamp-on meters, which are fitted on the outside surface of the pipe with no necessary modifications to the pipeline. This means meter setup is generally quick and the plant can continue normal operations throughout installation. Additionally, because many wastewater applications contain suspended solids and flow through the pipe at high velocities, meters that operate by use of moving parts in direct contact with the liquid will be subject to substantial wear and tear. Mechanical flow meters, for example, require regular cleaning since they are susceptible to clogging, periodic recalibration and repair of damaged parts. Clamp-on sensors never touch the flowing medium, thereby preventing the formation of deposits and virtually eliminating the need for time-consuming and costly maintenance. A wastewater treatment plant plays an important role in safeguarding the public water supply. Selecting proper flow measurement instrumentation is essential to ensure the plant maintains tight control of every step of the treatment process. Clamp-on ultrasonic flow technology is well suited for the challenging operating conditions that characterize the wastewater industry and, with time, can save plant operators a considerable amount of money.Case Study

The challenge

The flow instrumentation used by a municipal wastewater treatment plant in Louisiana experienced repeated electronics failures that prevented maintaining an accurate effluent flow signal. The facility needed a more reliable method of monitoring flow to ensure continuous compliance with regulations imposed by the Louisiana Department of Environmental Quality (LDEQ), so they contacted a global process instrumentation supplier for support.

The Solution

Because the plant expressed the need for minimal interruption of effluent flow to avoid interfering with reporting to the LDEQ, a local service partner of the supplier arrived at the site with a portable clamp-on ultrasonic flow meter demo unit. Since the sensors could be mounted externally, the meter was installed on the line within a few hours, and no downtime was necessary. Once the meter was turned on, the effluent flow signal was immediately restored and the reading remained accurate.

Thanks to the immediate success of the portable unit in responding to a months-long operational issue, the plant elected to purchase a permanent version of the clamp-on ultrasonic flow meter with dual transit-time and Doppler capabilities. Several years later, the meter continues to measure effluent flow with the same combination of accuracy and versatility demonstrated on the day of purchase.