In short, cooling towers are a type of hydraulic system used to remove heat from a given system and are used widely in chemical, power and heating, ventilation and air conditioning (HVAC) applications. Cooling towers use ambient air flow over heated water to evaporate a portion of the liquid, which results in evaporative cooling of the water. The cooled water is then collected in the basin of the tower, where it is ready to transfer heat from the process again. Makeup water is injected into the cooling tower basin to account for the water that is evaporated.

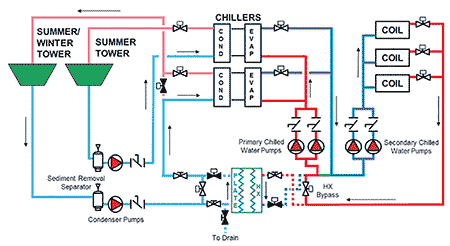

In commercial buildings, the cooled water in the basin of the cooling tower is pumped through chiller condensers to condense refrigerant from gas to liquid phase (Image 1). The chillers are used to create chilled water, which is circulated throughout the building. For the HVAC system in Image 1, condenser water pumps take the cooled water from the basin (blue) and supply the chiller condenser, where heat transfer takes place to condense refrigerant. The cooling water then warms and returns (red) to the top of the cooling tower. This summarizes the cooling tower side of the process. The other side of Image 1 is the chilled water side of the system, which is chilled by refrigerant in the chiller evaporator.

Cooling towers play a vital role in many industries, especially HVAC, and are an effective way to transfer heat in a cooling water system. For more information on cooling towers and how they function in a commercial HVAC system, please consult the Hydraulic Institute’s Guidebook for Commercial Building Services, available at pumps.org.