In a hypothetical world, if the Department of Energy (DOE) showed up at your plant to conduct an energy audit of the pump systems, what grade would you receive? Do you get an A … or an F? Plant owners and managers are faced with balancing scores of urgent priorities every day—stock holders on one side demanding the plant run continuously to keep the profits high, and engineering (reliability) and maintenance on the opposite side screaming, “we need to shut down to fix the plant.” Approximately 20 to 25 percent of the global electrical energy that goes to electrical motors is used to drive pumps. In recent years, you have likely noticed a major initiative in the industry to improve efficiency in pumps and their associated systems. This movement is led by the Hydraulic Institute and Pump Systems Matter, working in conjunction with the DOE to address energy consumed by all pumps currently in service and, of course, all future installations. The first part of the initiative’s proposal is to educate pump owners and operators on how to reduce energy requirements, then give them the tools to accomplish the task. In my personal opinion it is a herculean task, and I will also postulate that a reliable plant is most often an efficient plant and vice versa. Centrifugal pumps on average have an efficiency of 65 percent, with a few studies pushing the number higher. I would also point out that the “average” pump, despite its capability to be of higher efficiency, is likely operating somewhere below 45 percent. Industry research at numerous facilities both in the U.S. and Europe shows that well over 50 percent of the pumps in a given plant are not operating at their most efficient point, and there are many units operating at efficiency points as low as 10 percent.

Efficiency Trade Offs

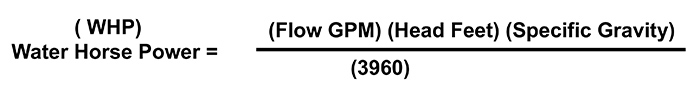

The pumps that are operated away from their best efficiency point (BEP), are worn out and have excessive clearances, or are simply the wrong pump for the application. Many pumps are not designed to be highly efficient on purpose, because they are designed for a specific service. For example, slurry, sewage and solids handling self-primer pumps are designed for reliability and long life at the expense of efficiency. Vortex, recessed impeller, disc and low flow-high head pumps are other examples of function over efficiency. Some pumps are assigned to an intermittent duty cycle when reliability and criticality supersedes efficiency. A pump that is required to run for five minutes once a week, ostensibly to lower a sump level, doesn’t need to be 75 percent efficient. It simply needs to operate reliably. The most efficient pump I ever dealt with was rated at 91 percent efficiency. It was a large single-stage horizontal split case pump designed for more than 200,000 gallons per minute. I was the engineer responsible for the installation of six of these pumps during a cold winter in North Dakota. Typically, the wider the passages in a pump (higher flow rates) the more efficient the pump will be because there is substantially less fluid friction on the casing and impeller surfaces. Most automobiles with gasoline engines are stretching to reach 20 percent thermal efficiency, though diesels are somewhat higher at close to 40 percent. I mention cars because they are something we can all relate to, and the public measures their efficiency in a different way than engineers who rate the thermal efficiency of the engine. The public measures car efficiency in miles per gallon. We can do the same with pumps if we look at gallons per minute (gpm) per kilowatt (kW) over some unit of time. That is, as a unit of work calculated from moving a unit of weight (fluid) over a unit of time. A gallon of water weighs about 8.3 pounds, and we propose to lift it and several more gallons some distance or height during some period of time (minutes in this case). The basic power unit required to accomplish this task will be measured in kW (over time) since the majority of pumps are driven by electric motors. The term to describe this viewpoint is called “specific energy,” so we look for the unit volume delivered by the pump divided by the actual power consumed, or simply the gpm divided by kilowatt-hours (kW-h). Using this concept it is easier to see the efficiency of the entire pump system and not just the pump. This is important because the prevailing issue is not the efficiency of the pump itself. Most pumps are not operated in an efficient manner due to how the system is designed or operated. Figure 1. Water horsepower assumes 100 percent efficiency. (Courtesy of the author)

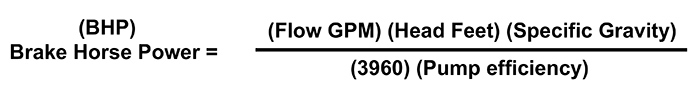

Figure 1. Water horsepower assumes 100 percent efficiency. (Courtesy of the author) Figure 2. Where pump efficiency is taken at the rated duty point and expressed as a decimal

Figure 2. Where pump efficiency is taken at the rated duty point and expressed as a decimal