These pumps offer efficiency and reliability in complex industrial operations.

08/10/2015

Pumps make industrial manufacturing possible. Every day, thousands of industries around the world rely on various pumping technologies to move raw materials and end products through the production process. Whether handling lube oils, paints and coatings, or working in applications from heat transfer to chemical processing, pumps must reliably, efficiently and safely transfer an array of fluids, all of which have unique—and often challenging—handling characteristics. If a pump is the weak link in the production process, the entire operation will be compromised, with the downtime required for repair or replacement eating away at production quotas and the bottom line.

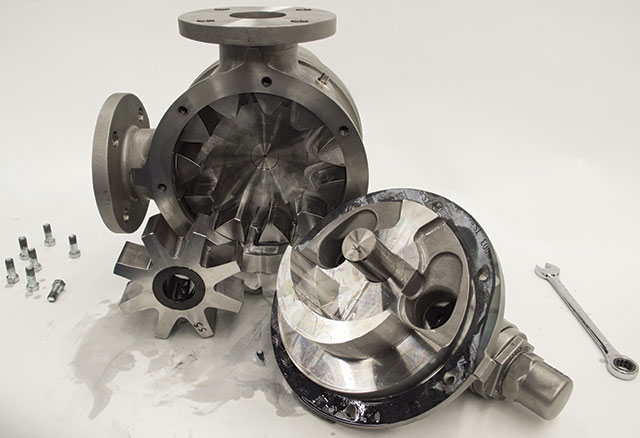

Image 1. In order to fashion a handling and transfer operation that optimizes reliability, efficiency and safety, many chemical processors are making the decision to install internal gear pumps. (Images courtesy of PSG)

Image 1. In order to fashion a handling and transfer operation that optimizes reliability, efficiency and safety, many chemical processors are making the decision to install internal gear pumps. (Images courtesy of PSG) Image 2. No acid, polymer, resin or caustic has the same handling characteristics, which makes pump versatility a primary concern for chemical processors. These internal gear pumps overcome many handling concerns by featuring a method of operation that can successfully and safely transfer fluids of differing viscosities and chemical makeups.

Image 2. No acid, polymer, resin or caustic has the same handling characteristics, which makes pump versatility a primary concern for chemical processors. These internal gear pumps overcome many handling concerns by featuring a method of operation that can successfully and safely transfer fluids of differing viscosities and chemical makeups.- The rotor and idler gears un-mesh at the suction port to create an atmospheric vacuum that draws fluid into the pump. As the rotor turns, the fluid is forced between the rotor teeth and idler teeth.

- Continual rotation of the rotor forces the fluid through a crescent-shaped area within the wetted path. The crescent-shaped area divides the fluid and acts as a barrier between the inlet and discharge ports.

- As the rotor continues rotation, the fluid is forced past the crescent-shaped area and moves toward the discharge port.

- As the rotor completes its rotation, the rotor and idler teeth engage, forcing the fluid through the discharge port of the pump.

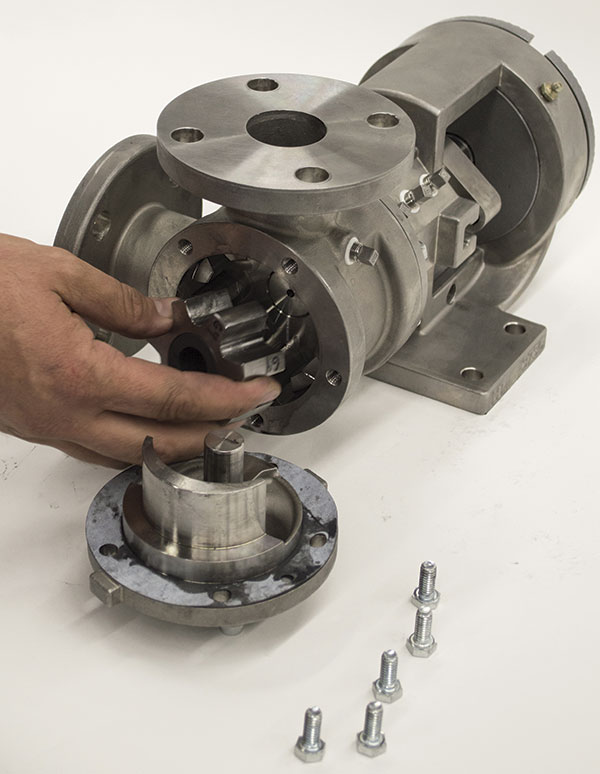

Image 3. Internal gear pumps feature a unique design that features only two moving parts, a rotor and idler gear, which allows them to operate equally well in either direction and deliver positive, non-pulsating flow of the liquid being handled.

Image 3. Internal gear pumps feature a unique design that features only two moving parts, a rotor and idler gear, which allows them to operate equally well in either direction and deliver positive, non-pulsating flow of the liquid being handled. Image 4. Internal gear pumps feature a unique design that have only two moving parts, a rotor and idler gear, which allows them to operate equally well in either direction and deliver positive, non-pulsating flow of the liquid being handled.

Image 4. Internal gear pumps feature a unique design that have only two moving parts, a rotor and idler gear, which allows them to operate equally well in either direction and deliver positive, non-pulsating flow of the liquid being handled. Image 5. Fluid transfer touches every stage of the manufacturing process and is vital for overall process success.

Image 5. Fluid transfer touches every stage of the manufacturing process and is vital for overall process success.