A multistage pump is a type of rotodynamic pump, meaning it uses rotating impellers to impart energy to the fluid it is pumping. What differentiates multistage pumps from other pumps is that they feature three or more impellers arranged in series, with each stage of the pump consisting of an impeller, diffuser or volute and guide vanes or crossover within the same casing. From one stage to the next, the pressure of the pumped fluid increases, allowing multistage pumps to achieve higher discharge pressures than their single-stage counterparts.

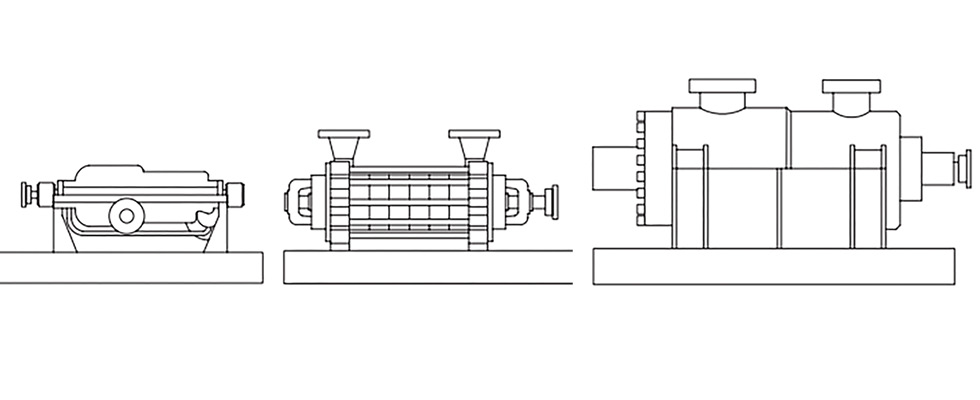

Three types of multistage pumps are overhung, between bearing and vertically suspended, as defined in ANSI/HI 14.1-14.2 Rotodynamic Pumps for Nomenclature and Definition. Focusing on the between bearing category, three classifications are: axially split (BB3), radially split single casing (BB4) and double casing (BB5) types (Image 1). In all three of these pump types, the pump and driver have separate shafts, which are flexibly coupled, and the pump has two integral bearing housings to absorb all axial and radial hydraulic loads.

BB3 type pumps are axially split casings, which are commonly referred to as horizontally split. This means the casing has a top and bottom portion, and the upper casing can be removed to expose the rotating assembly. In this type, the multistage impellers are grouped in a back-to-back configuration. For example, a 10-stage pump may have five stages facing left and five stages facing right. They are oriented opposite each other around a high-pressure breakdown bushing to balance axial thrust and minimize the loads experienced by the bearings. They are commonly used in applications for boiler feed, mine dewatering and other high-pressure services.

BB4 type pumps, also called ring-section pumps, have radially split casings that must be disassembled by the removal of each impeller and stage casing. The radial split design allows this type to operate at higher pressures. Additionally, the impellers are oriented in the same direction, so an axial thrust compensation device is required. These pumps are used in similar services as the BB3 type and are commonly used in combined cycle power plants as the boiler feed pump because they are well suited for the typical load swings.

BB5 type pumps, also called double-case or barrel pumps, have radially split outer casings in which the internal casings can be withdrawn from one end of the outer casing. BB5 type pumps are essentially BB4 or BB3 type pumps with an added external casing. This casing forms a pressure boundary and allows for safe containment of fluids at extreme pressures and temperatures. These pumps are well suited for the same high-pressure applications as the BB3 and BB4 type pumps but are typically used in higher pressure applications. The largest pumps in the world (with respect to power) are BB5 types.

For more information on multistage pumps, please consult the ANSI/HI 14.1-14.2 and ANSI/HI 14.3 standards, available on pumps.org.