The U.S. Department of Energy (DOE) is implementing minimum efficiency limits on pumping systems and their components. Meanwhile, end users are demanding systems with ever higher efficiencies. One way pump manufacturers satisfy the needs of both groups is by introducing solutions that make it possible for pumping systems to change speed to maintain peak efficiency when output demand changes. On pumping systems driven by electric motors, this efficiency boost is typically achieved by adding a variable frequency drive (VFD) to the motor. A VFD is an adjustable speed drive that controls alternating current (AC) motor speed and torque by varying motor input frequency and voltage. Many in the pump industry are familiar with how VFDs work and their efficiency benefits. What is not so commonly understood is how to protect motors from the potentially harmful effects that a VFD can produce and how to reduce these effects in a pumping system.

Protecting a Motor from a PWM Waveform

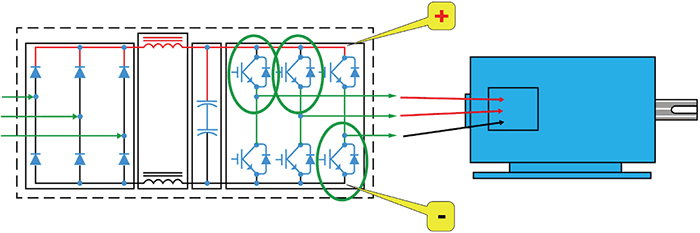

Many motor manufacturers offer motors designed to run on a VFD or inverter. These motors have been specially designed to be operated when powered by a VFD’s pulse width modulated (PWM) power waveform. PWM is a modulation technique used primarily to control the supply of the voltage and current waveform to a motor. It is often preferred because it is a highly efficient method of motor speed control. A PWM waveform can, however, create issues within a motor. For example, it can cause a motor winding to experience voltage spikes that are well above the rated voltage of both the motor and standard motor winding limits. Motors that are to be used with a VFD, therefore, should have improved insulating materials and processes—compared to a standard insulation system—to protect against voltage spikes well above their rated voltage. According to National Electrical Manufacturer’s Association (NEMA) MG1 Part 31, motors with a voltage rating of 600 volts or less that are used on VFDs should have windings that protect, at a minimum, against a voltage spike of 3.1 times the rated voltage. For motors with a voltage rating greater than 600 volts, the minimum is 2.04 times the motor’s rated voltage. Image 1. Common mode voltage (Image courtesy of Nidec Motor Corporation)

Image 1. Common mode voltage (Image courtesy of Nidec Motor Corporation)