There is no standard that states how pump manufacturers should present performance data for their models, but data is reported in a similar fashion.

Positive displacement (PD) pumps deliver a relatively constant flow as a function of differential pressure; therefore, their performance data is often displayed as a function of speed. Additionally, positive displacement pumps are often applied in viscous pumping applications, so their representative test data is often represented when pumping oil of a certain viscosity. PD performance data is either presented in table or curve format. It will show how the pump flow rate changes with speed and how the power changes as a function of differential pressure and flow rate.

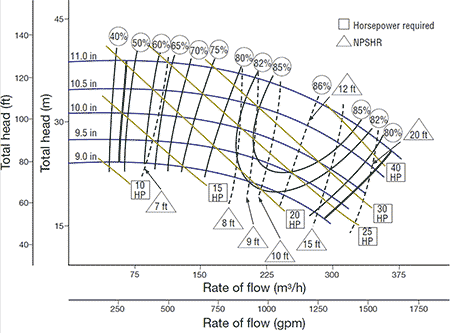

Centrifugal pumps have a wide range of flow as a function of differential pressure or total head. Therefore, their performance data is displayed with flow rate on the horizontal axis and pump total head on the vertical axis, and this will be shown for multiple impeller trims. The pump model curve will also communicate the pump efficiency, pump input power and net positive suction head required (NPSHr) as a function of flow rate.

These could be individual curves for each impeller diameter trim, or they could be shown as isolines that intersect the total head versus flow rate curves (Image 1). The point where the isolines intersect the total head curve is the point that the NPSHr, pump input power and efficiency apply to. So, if you looked at the 1000 gallons per minute (gpm) flow point for the 11-inch impeller, the total head would be about 120 feet, the pump efficiency would be about 85%, the pump input power would be about 35 horsepower and the NPSHr would be about 9.5 feet.

Also, this data represents the performance for water at ambient temperature. For different fluid properties, such as density or viscosity, the performance would need to be adjusted per ANSI/HI 9.6.7 Rotodynamic Pumps Guideline for Effects of Viscosity on Performance.

For more information on pump drives, drivers, pump curves and much more, refer to the recently launched HI University Pump System Certification Level 1 On-Demand training at training.pumps.org.