In short, the term “petrochemical” refers to the chemical products or byproducts derived from petroleum refining. Most petrochemicals can be separated into two classes: olefins, such as ethylene and propylene, and aromatics, such as benzene and toluene. All of them are used extensively in the fields of energy and synthetic material production.

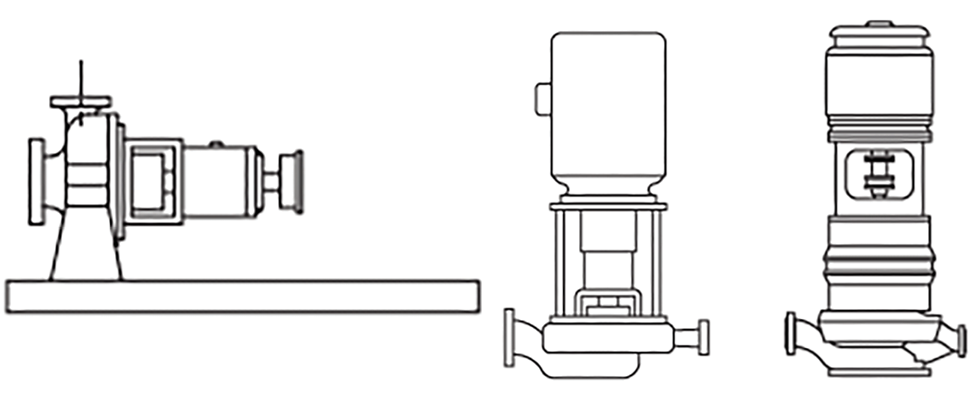

According to ANSI/HI 14.3 Rotodynamic Pumps for Design and Application, there are three centrifugal pump types in particular that are used most in petrochemical applications. All three pumps fall into the overhung (OH) category, meaning their impellers are mounted at the end of their shafts, cantilevered (or overhung) from their bearing supports. Within the OH class, the pumps most suited for petrochemical applications are of types OH2, OH3 and OH6, which are shown in Image 1.

OH2 pumps are horizontal flexibly coupled pumps and their casing has mounts at the shaft centerline, which allows for even growth over large temperature fluctuations. OH3 pumps are vertically mounted, flexibly coupled and have in-line pump casings. In this design, the piping connections and fluid enter and exit the casing in a straight line. OH6 pumps are typically oriented vertically like the OH3 pump type and are also in-line pump casings. However, these are high rotational speed pumps, so they include an integral gear box between the motor shaft and the pump shaft. These pumps are designed for relatively low flow rates at relatively high differential pressure.

For more information on the petrochemical industry and centrifugal pumps used in these applications, refer to ANSI/HI 14.3 at pumps.org/standards.