The global chemical industry is an imperative piece of the worldwide economy. It is responsible for converting raw materials into tens of thousands of various products. In 2022, the global chemical industry generated more than $5.7 trillion. Chemical imports and exports also amounted to trillions in revenue with Europe and the Asia-Pacific region ranking first and second, respectively, according to a Statista report.

Because this industry plays a major role in the success of the global economy, chemical plants must have the right equipment to process these chemicals. Not all chemicals, however, have the same composition, making some more difficult to handle than others. Chemicals classified as dangerous present a variety of challenges for chemical plants.

Dangerous chemicals are identified as those with properties that can cause physical harm to people, create health hazards or damage the environment. These chemicals tend to be highly corrosive, potentially explosive or toxic. Examples of dangerous chemicals include ammonia, chlorine, formaldehyde, hydrogen bromide, nitric acid, sulfur dioxide and sulfuric acid, all of which are classified as high on the hazard index, according to the United States Occupational Safety and Health Administration (OSHA).

Though these chemicals are hazardous, the world would not function the same without them, as they are used to make thousands of items. Sulfuric acid, for example, ranks as one of the top elements for industrial use, most notably in producing agricultural fertilizers, according to the U.S. Geological Society (USGS). In 2018, the U.S. produced 25.8 million metric tons of sulfuric acid, which can be found in the production of dyes, alcohols, plastics, rubber, ether, glue, paints, explosives, drugs, pharmaceutical products, soaps and detergents, pulp and paper, wood preservatives and petroleum products.

Petrochemicals are also hazardous variants that hold significance in the global economy. According to a Statista report, the petrochemical industry was valued at $584.5 billion in 2022, displaying the growing demand for petrochemical products. Petrochemicals are organic chemicals made from hydrocarbon raw materials sourced from crude oil, natural gas or coal. Dangerous aromatics such as benzene, toluene and xylenes—along with olefins such as ethylene, propylene and butadiene—are the primary building-block chemicals in producing petrochemical intermediates and final products. Many dangerous petrochemicals are processed into polymers for use in plastics, resins, fibers, elastomers and coatings. Petrochemicals also make a wide range of end-use products such as detergents, adhesives, solvents, plasticizers and lubricants.

Given the importance of dangerous chemicals to the global economy, plant operators need to select the right pumps and materials to ensure these elements are safely processed and transferred without creating a safety or environmental hazard.

Comparing Pump Technologies

Multiple pump technologies can process dangerous chemicals, but some are more efficient than others for the job. Gear pumps push chemicals through a mesh of teeth between two rotating gears, using tight internal clearances to optimize volumetric efficiency and minimize slip. When first put into service, those internal clearances are at their tightest. But as the pump continues to operate, the meshing gears can wear down with each use, compromising volumetric efficiency and allowing slip while creating inconsistent flow rates and increasing energy consumption. Lobe pumps have similar functionality and disadvantages.

Centrifugal pumps, while a reliable technology, can also have trouble processing dangerous chemicals. This technology, like gear pumps, creates friction when processing fluids, leading to shearing. This damages and alters the composition of the chemicals, which compromises their integrity. When processing dangerous chemicals, operators should consider a pump that is chemically compatible with all wetted parts, operates leak-free, has constant flow rates with no slippage and is reliable in harsh conditions and atmospheres.

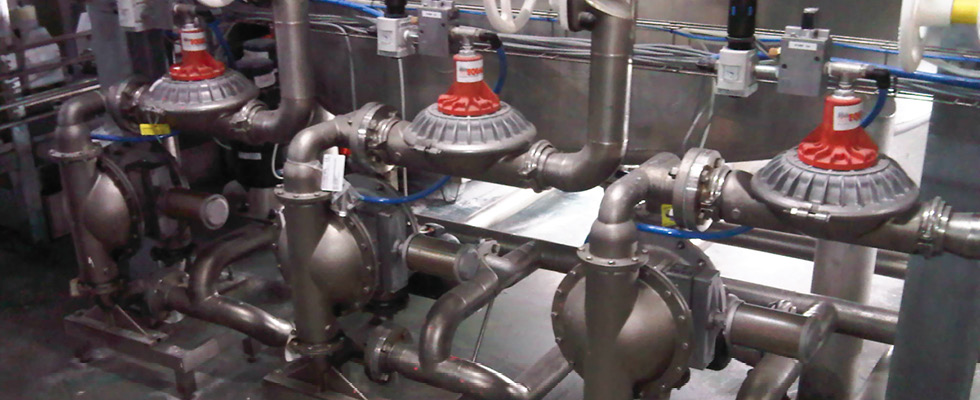

One option that meets those criteria is air-operated double-diaphragm (AODD) technology. AODD pumps are reciprocating, positive displacement pumps driven by an air distribution system. These pumps only have a few wetted parts and offer a variety of compatible materials to meet the needs of the processed chemicals. AODD pumps are virtually leak-free because they do not have mechanical seals, eliminating a common leak point in comparable technologies.

Flow rates stay consistent in AODD pumps due to their gentle pumping action, eliminating shear and maintaining the integrity of the processed chemicals. Operationally, AODD pumps are flexible, allowing operators to use the same pump for different flow rates and needs simply by adjusting the air supply.

Using an air distribution system instead of an electric motor makes AODD pumps an apparent choice for chemical-processing plants, which have access to compressed air. This allows an AODD pump to function as a plug-and-play device that does not require infrastructure adjustments or upgrades to accommodate.

Additionally, AODD pumps can deadhead without damage because they rely on air to operate. This functionality also allows operators to save on energy costs. While AODD pumps consume a small volume of air after each stroke, high-efficiency air distribution systems can mitigate this with an air control spool, reducing air consumption by up to 60%.

Pump Construction & Materials

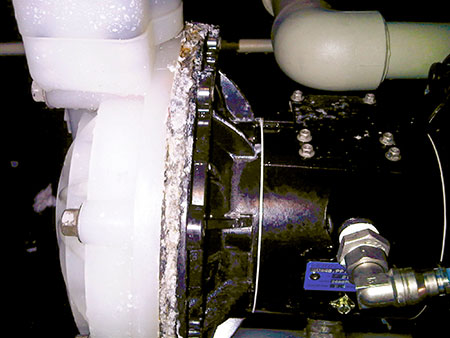

While AODD pumps are a prime choice for processing dangerous chemicals, another part of the technology’s success relies on the construction of the apparatus and the diaphragms used. Without the proper construction, a pump handling these chemicals will eventually wear down, compromising functionality and creating safety hazards.

Common chemical pump materials include stainless steel, ductile iron, Hastelloy (Alloy C), polypropylene and polyvinylidene fluoride (PVDF). Some companies also offer special materials like super duplex. Of these materials, two excellent choices for handling dangerous chemicals are PVDF and Alloy C.

PVDF and Alloy C offer durability and robust chemical compatibility compared with plastic and metal alternatives. For example, standard plastic and aluminum materials are prone to erosion when handling dangerous chemicals. PVDF and Alloy C can function optimally in any application that processes these chemicals. They do not suffer from erosion or lose their integrity, offering resistance to abrasion and corrosion compared with their counterparts. These two materials also work in applications beyond chemical processing, such as oil and gas, marine and seawater.

With the proper pump construction, selecting the right diaphragm becomes the next essential choice to ensure optimal chemical processing, as well as pump longevity and functionality. There are three main material families of AODD pump diaphragms: rubber, thermoplastic elastomer (TPE) and polytetrafluoroethylene (PTFE). Each material offers benefits in varying applications, but PTFE may be best suited for dangerous chemicals.

PTFE’s chemical makeup allows it to operate with a wide range of fluids, even highly aggressive variations, such as hydrocarbons, acids, caustics, ketones and acetates. Featuring longevity and moderate abrasion resistance, PTFE works well with dangerous chemicals. The material also has an operating temperature limit between 4 and 104 C (40 to 220 F).

The importance of the chemicals industry to the global economy and supply chain means operators have a responsibility to handle and process a variety of chemicals in the most efficient and effective way possible, keeping costs low and hazards minimal to nonexistent.