End users must be aware of the valve emission standards to meet industry requirements.

04/16/2014

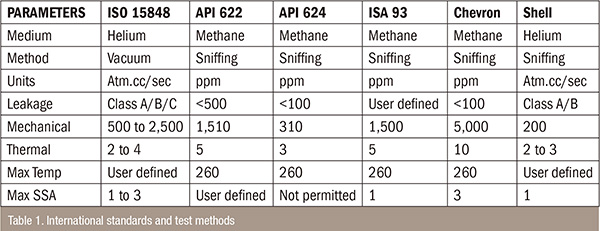

An article in the October 2013 issue of Pumps & Systems discussed how to minimize leaks by applying proper design and material-selection standards. This article details new codes that have been established because the International Organization for Standardization (ISO) is currently updating certain standards, including ISO 15848 Parts 1 and 2. American Petroleum Institute (API) 624 was updated in February 2014. A summary of the standards and their test methods are shown in Table 1.

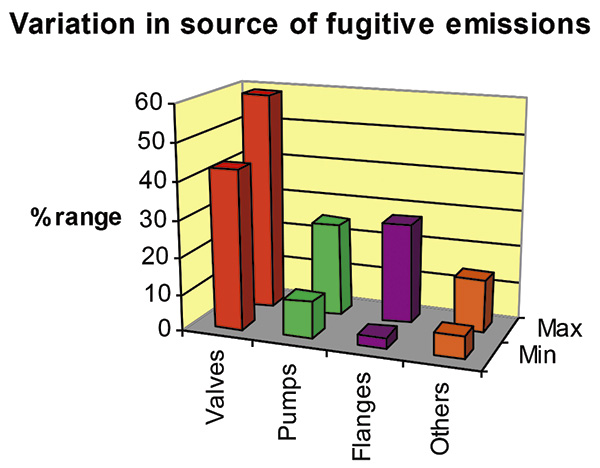

- Leaks greater than 10,000 parts per million (ppm) are being eliminated.

- Leakage to 500 ppm maximum is being limited.

- New API 624 (released February 2014) has moved toward allowable leakages of 100 ppm or lower.

- Awareness of environmental initiatives in North America has grown tremendously, and such initiatives have given visibility to projects such as the Keystone XL Pipeline.

- Hydraulic fracturing is being examined more closely and codes and regulations in this space have been updated.

- Policy makers are becoming strict and inspectors are imposing fines when necessary.

- Maximum stem to seal tolerance allowance (finishing)

- Criteria on leakage rates

- Maximum temperatures

- Minimum temperatures

- Leakage class

- Cycles

- The total cost of the valve

- Maintenance, shutdown and reliability costs

- The manpower required

- Meeting corporate safety and regulations

- Their industry image to be green and a clean producer