With more than 20 years of experience in the oil and gas industry, Lukoil, a Russian oil and gas business, aspired to expand its oil and gas fields. For the expansion, Lukoil selected the Bolshekhetskaya depression in West Siberia, where large deposits of ceromanian gas lay. Developing and constructing a compressor station to connect the fields would increase the total capacity of the pipeline. The compressor design had to produce a high discharge pressure. In addition to the pressure gain required to compensate for the piping frictional losses, the discharge pressure of the compressor also supports a refrigeration process applied to the gas at the plant outlet. This refrigeration process, based on a throttling principle, is required to cool the gas sufficiently to keep the buried piping temperatures from thawing the permafrost. The permafrost helps maintain a stable support for the buried piping.

The Challenge

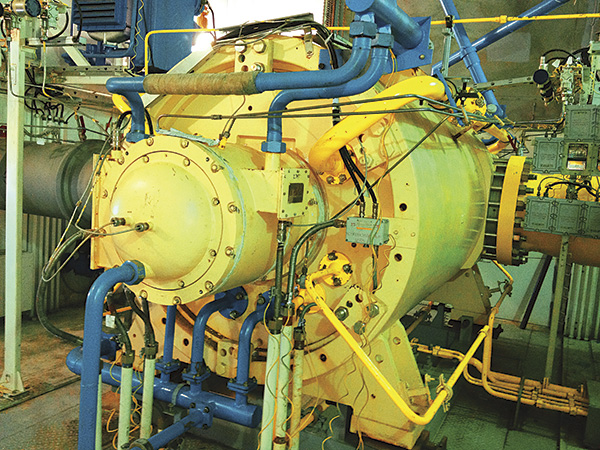

Lukoil partnered with Sumy Frunze, an oil and gas equipment manufacturer, to develop centrifugal compressors that could withstand the frigid Siberian conditions. The compressors would allow the station to pump 12 billion cubic meters of gas per year to another station, furthering the central gas pipeline of Russia. Providing such high compressor discharge pressures with reasonable drive power requires compressors with high efficiency. Natural gas compressor at the Lukoil Nahodkaskaya site in Western Siberia

Natural gas compressor at the Lukoil Nahodkaskaya site in Western Siberia Compressor building at the Lukoil Nahodkaskaya site in Western Siberia

Compressor building at the Lukoil Nahodkaskaya site in Western Siberia