Air-operated double-diaphragm (AODD) pumps are integral to industries managing challenging fluids, particularly in chemical processing and wastewater treatment. Their capacity to operate under harsh conditions while ensuring safety and efficiency distinguishes them from other pump technologies. AODD pumps are recognized for their versatility, allowing operators to employ a single pump type across various applications without significant infrastructure modifications.

Importance of AODD Pumps in Key Industries

AODD pumps play a crucial role in wastewater treatment facilities, which face challenges while managing both industrial and municipal waste streams. These streams often contain corrosive chemicals, abrasive sludges and suspended solids, which can cause considerable wear on conventional pumping systems. AODD pumps are engineered to withstand these harsh conditions due to their robust construction and operational features.

In the wastewater sector, the ability to handle varying flow rates and solid concentrations is vital. AODD pumps can easily adapt to changes in the composition of waste, ensuring treatment processes remain efficient and effective. Their design reduces the risk of clogging and ensures continuous operation, which is crucial for maintaining environmental compliance.

In the chemical processing industry, the need for reliable and efficient pumps is even more pronounced. AODD pumps excel at managing aggressive fluids while maintaining the integrity of shear-sensitive fluids. Their design can eliminate the need for mechanical seals, which can be prone to failure in such environments, thus ensuring safe operation.

The versatility of AODD pumps is another key advantage. They can handle a wide range of fluids—from corrosive acids to viscous slurries—making them suitable for various applications within the chemical sector. This compatibility allows for reduced downtime and lower inventory costs.

The Need for Continuous Innovation

In today’s rapidly evolving industrial landscape, continuous innovation is critical. Stricter regulations, rising operational costs and the growing demand for sustainable practices push industries—including chemical processing and wastewater treatment—to adopt advanced technologies. By fostering a culture of innovation, organizations can enhance efficiency, reduce waste and improve safety measures.

Technological advancements are essential for meeting the demands of modern industrial applications. Innovations in pump technology, such as air valve innovations, demonstrate how manufacturers can address industry challenges effectively. Continuous improvement not only benefits individual companies but also enhances overall industry performance, paving the way for a more sustainable future.

Air Valve Design in AODD Pumps

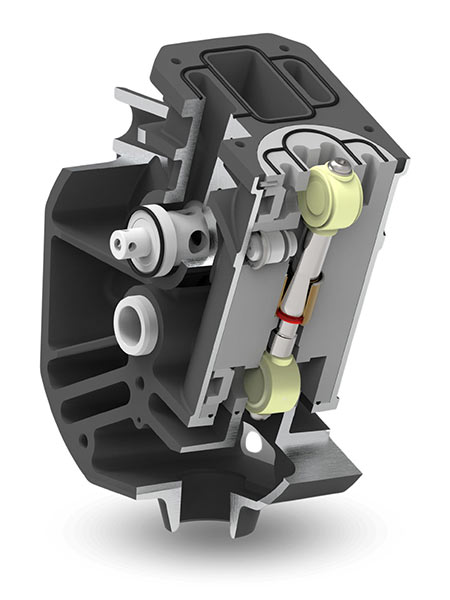

One of the most significant advancements in AODD pump technology lies in the design of the air valve. The air valve controls the pump’s operation by precisely directing compressed air within the pump. It prevents stalling, optimizes air consumption and regulates fluid pulsations as well as pump vibrations. Recent innovations in air valve systems have improved both performance and reliability.

- Increased efficiency: Enhanced energy efficiency reduces overall operational costs, making AODD pumps more economically viable over time. For instance, reducing air consumption can lead to savings on energy bills, which is particularly beneficial for facilities operating multiple production shifts.

- Improved reliability: The advanced design minimizes the risk of stalling and failure due to icing, ensuring consistent performance in challenging environments. This reliability is essential in sectors where downtime can lead to regulatory penalties or excessive losses of productivity.

- Reduced maintenance needs: AODD pumps equipped with this air valve can continue operating with minimal interruptions. The design allows for easier maintenance and faster repair, which is crucial for industries that require continuous operation. In many cases, the air valve can be serviced without removing the pump from the installation, reducing downtime and improving overall operational efficiency. This feature is particularly beneficial in industries where consistent operation is paramount.

The air valve technology in AODD pumps enhances performance in both chemical processing and wastewater treatment. In chemical processing, it enables precise handling of corrosive and abrasive fluids, improving safety and product quality. For wastewater treatment, the pumps effectively manage sludges and chemicals, ensuring compliance with environmental regulations. With reduced maintenance needs and increased operational efficiency, these advanced AODD pumps are essential for industries that operate in harsh conditions.