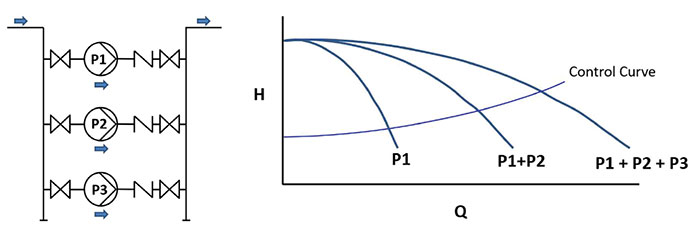

This pump setup allows the ability to add or subtract flow capacity.

Grundfos

01/29/2019

Many of today’s pumps are installed to operate under variable flow conditions, so understanding the concept of parallel pump control is a must. First, it is critical to know how parallel pumps will operate upon installation. The idea behind parallel connected pumps is the ability to add or subtract flow capacity and/or provide redundancy. Image 1 shows three parallel connected pumps. For the purpose of this discussion, assume they are each of equal capacity. The pump head-capacity curves are shown in Image 2.

Image 1 (left). Three parallel connected pumps. Image 2 (right). Pump head-capacity curves (Images courtesy of Grundfos)

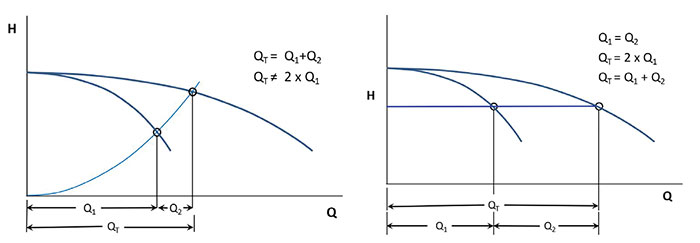

Image 1 (left). Three parallel connected pumps. Image 2 (right). Pump head-capacity curves (Images courtesy of Grundfos) Image 3 (left). System curve starts at zero flow/zero head. Image 4 (right). Head required in system is constant

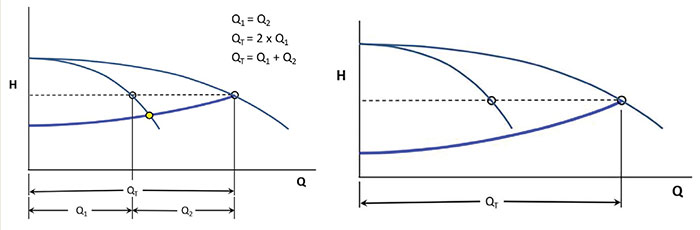

Image 3 (left). System curve starts at zero flow/zero head. Image 4 (right). Head required in system is constant Image 5 (left). Realistic control curve. Image 6 (right). Control curve does not intersect head capacity curve for Pump 1.

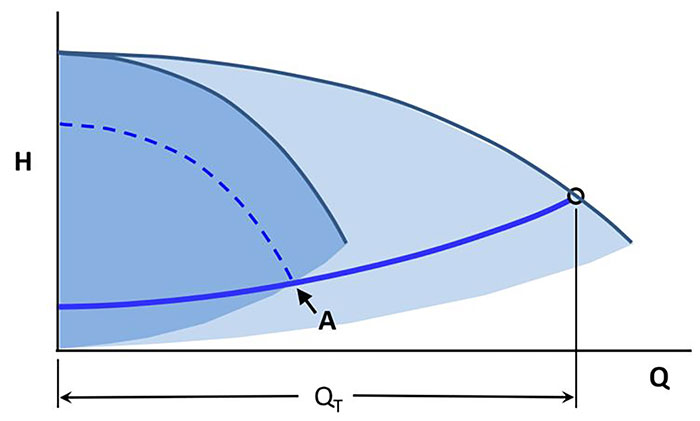

Image 5 (left). Realistic control curve. Image 6 (right). Control curve does not intersect head capacity curve for Pump 1. Image 7. Operating range when variable speed drives are used for pump control

Image 7. Operating range when variable speed drives are used for pump control