Part 1 of this article (Pumps & Systems, September 2023) explored the effectiveness of conventional Cleaning in Place (CIP) methods and that of impulse cleaning, which relies on the controlled pulsed injection of compressed air into a throttled water flow. Part 2 delves into the intricacies of integrating pigging technology, discussing its advantages and challenges as well as key considerations for implementation.

Reducing Product Waste With Pigging Technology

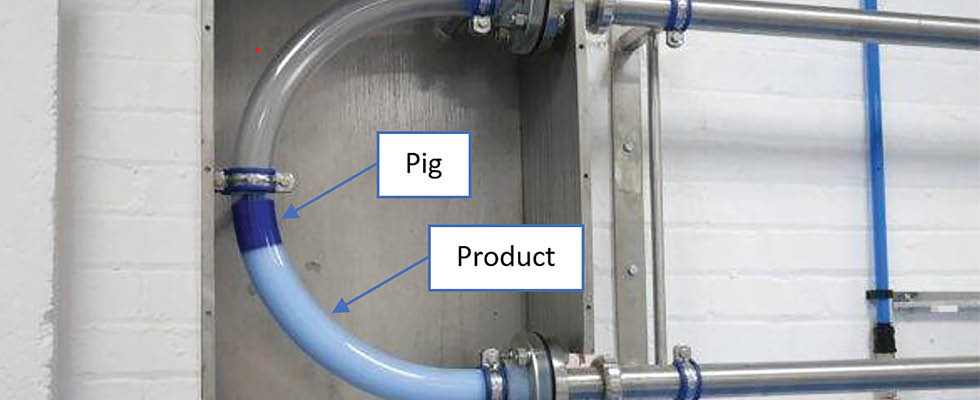

Pigging is a technique that has gained popularity in recent years as an effective means to reduce product loss during CIP and product transfer processes. Pigging involves the use of a specialized projectile, known as a “pig,” which is designed to travel through the process lines, pushing out the residual product ahead of it and collecting it for reprocessing or disposal.

How Pigging Works

Product recovery: Before the CIP process begins, the pig is inserted into the process lines. By using the product or compressed air as the propellant, the pig effectively recovers the remaining product, leaving minimal product residues in the lines.

Reduced cross-contamination: As the pig removes the bulk of the product from the lines, the risk of cross-contamination during cleaning is significantly reduced, ensuring the highest standards of hygiene.

Resource savings: Pigging reduces the amount of water and cleaning agents needed for the CIP process since the majority of the product is recovered, resulting in substantial resource savings.

Environmental benefits: The reduction in water and chemical usage also leads to a decrease in wastewater generation, contributing to the overall environmental sustainability of the process.

Advantages of Pigging Technology

Minimized product loss: Pigging technology can recover up to 99% of product residues, ensuring valuable product is not wasted during cleaning.

Enhanced efficiency: By reducing the amount of product in the lines, the subsequent CIP process becomes more efficient and requires fewer resources.

Cost savings: The recovery of product and reduced resource consumption lead to cost savings, making pigging a financially attractive investment.

Pigging Challenges

Implementing a pigging system can present several challenges for industries looking to enhance their cleaning processes. One primary challenge is the initial investment required to install the necessary infrastructure, including pig launchers and receivers, along with the pigging equipment itself.

The retrofitting of existing pipelines can be complex and may entail disruptions to regular operations during the installation phase. Additionally, the selection of the right pigging technology that suits the specific application and pipeline characteristics can be daunting. Maintaining and cleaning the pigging equipment regularly is another challenge, as neglecting maintenance can lead to reduced efficiency and compromised cleaning results.

Moreover, employee training is essential to ensure proper handling of pigging equipment and adherence to safety protocols. Despite these challenges, the potential benefits, such as reduced product loss and enhanced cleaning efficiency, make pigging systems a valuable investment for industries seeking to optimize their cleaning processes.

The Integrated Approach

The integration of conventional CIP, pigging and impulse cleaning technologies culminates in a robust CIP system that yields exceptional cleaning performance and significant long-run cost reductions. By leveraging the strengths of each technology, this integrated approach delivers a comprehensive and efficient cleaning solution that surpasses the capabilities of traditional standalone methods. The combination of pigging technology at the onset of the cleaning sequence enables recovery of the product that remains in the piping system, reducing product loss and its associated costs.

Subsequently, the application of impulse cleaning technology enhances the cleaning process by generating increased wall shear stresses, driving fluid velocities along inner surfaces while reducing required volume of cleaning fluid. This results in the removal of persistent deposits and contaminants, elevating hygiene standards and product quality at a lower cost.

Key Considerations for Implementation

Prior to installation, it is important to evaluate design intent and site capabilities, including existing compressed air, electrical and water flow capacities. Adequate compressed air supply is essential for efficient impulse cleaning and pigging processes. Users should opt for a centralized location to reduce costs and improve cleaning velocities. Assess available utility streams for heating the cleaning liquid if necessary.

Proper evaluation of these factors will optimize cleaning performance and overall efficiency in the integrated CIP system. Design will be the most critical step in a user maximizing their clean goals. To accommodate the pigging process, several crucial design considerations should be evaluated to ensure seamless integration and optimal performance. The first aspect to focus on is the pipeline design, where the selection of the appropriate material and dimensions plays a critical role. Smooth and seamless pipelines minimize friction, facilitating the smooth movement of pigs within the system. Careful consideration of the pipeline’s internal diameter is necessary to accommodate the size and type of pigs used for the specific application. There are predesign pipe and tube fittings that specifically address these requirements.

Additionally, pigging frequency and operational objectives must be determined to design an effective system. The operational goals, whether focused on cleaning, product recovery or batching, should align with the selected type of pigs and a well-defined pigging schedule. Properly sized and designed pig launchers and receivers are crucial for safe and efficient pigging operations.

The selection and arrangement of tanks should align with the specific cleaning requirements and process parameters. Careful evaluation of the process flow, cleaning objectives and production schedules will help determine the number of tanks needed and their capacities. Utilizing tanks of suitable volumes ensures efficient cleaning cycles and minimizes downtime, optimizing the overall process.

Defining the chemical sequences is vital for achieving effective cleaning performance. Determining the correct sequence of cleaning agents, including detergents and sanitizers, ensures thorough removal of contaminants and persistent deposits. Each cleaning stage must be precisely tailored to the unique process requirements and the type of residue to be cleaned. Sequencing the chemicals correctly will avoid any potential reactions or undesired interactions between cleaning agents, enhancing the cleaning process’s overall effectiveness.

Pumps and valves are crucial components in an integrated CIP system, as they facilitate the precise delivery of cleaning agents and control the flow of fluids during the cleaning process. Selecting pumps and valves that are compatible with the cleaning agents used and can handle the required flow rates is vital for consistent and efficient cleaning operations. Properly sized pumps and valves enable smooth fluid movement through the system, minimizing pressure drops and optimizing cleaning performance.

Instrumentation and controls play a pivotal role in defining and executing the cleaning sequence. Utilizing advanced sensors and instruments allows real-time monitoring of process parameters, such as temperature, pressure and flow rates. The data collected from these instruments provides valuable insights for ensuring the cleaning sequence’s accuracy and efficiency. Additionally, implementing an advanced control system enables automated and precise sequencing of pumps, valves and cleaning agents, minimizing the risk of errors and maximizing the repeatability and reliability of the cleaning process.

The combination of traditional CIP methods, impulse cleaning and pigging represents an exciting and promising approach that combines chemical and mechanical cleaning principles to yield significantly improved results. By integrating the strengths of each technology, this approach offers superior cleaning performance, reduced resource consumption and enhanced hygiene standards.