Ultraviolet C (UVC) LED-based treatment systems can be used in applications requiring on-demand or intermittent drinking water disinfection.

In the case of point-of-entry (POE) systems for whole home treatment, the instant on/off nature of this solid-state technology improves the system’s overall energy efficiency while extending light source replacement cycles—and reducing unplanned maintenance.

Designing for End of Life

Low and medium pressure mercury lamps have long been utilized in POE disinfection systems. However, due to an assortment of regulatory, technical and environmental concerns, many manufacturers are now looking to develop entirely new systems using high power UVC LEDs.

In POE applications, the system’s end of life is of the utmost importance—it is not the first glass of water a user needs to be concerned about; it is the last. While UVC LEDs can offer a longer lifetime than traditional mercury lamps, lifetime is not a fixed specification.

Managing the product’s end of life requires careful planning, and that starts at the design phase. Engineers will ultimately need to determine what amount of UVC power will be required for that last glass of water by calculating their design’s operational requirements, the cumulative LED “on time,” and then determining the product’s projected lifetime.

As designers look to incorporate UVC LEDs into these systems, it is important to consider the key learnings from the point-of-use (POU) market. Early POU reactor designs tried to mimic mercury bulbs in every way, from form and fit to continuous operation. However, by understanding the differences in LED wavelength, emission pattern and instant on/off capability, product engineers were able to open the design space for smaller, more efficient reactors. This has led to consumer POU systems with UVC LED reactors that last the full lifetime of the product.

POE system designers can take this learned approach to address higher flow applications and consider how to link their requirements to the design efficiency of UVC LEDs. For example, swapping a 15-watt mercury lamp for a 15-watt UVC LED will not result in the most efficient overall design. When designing with LEDs, a POE application will have clearly defined inputs, such as flow rates and disinfection requirements. LEDs offer designers a much greater range of output power, wavelength and drive current options to meet these inputs.

Linking Application Requirements to LED Specifications

The first step involves establishing the water quality and the disinfection target microbe(s). Since suspended water particles can shield microbes and absorb UVC light, water quality will determine the amount of UVC light needed for disinfection.

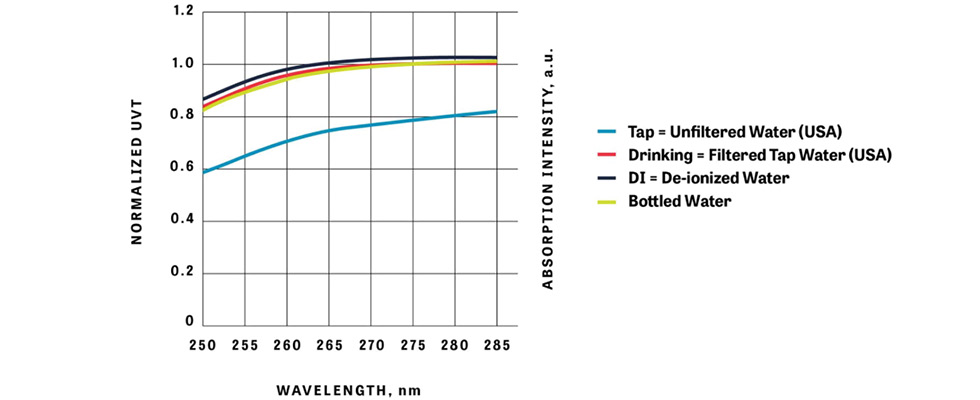

Ultraviolet transmissivity (UVT) is crucial, as it determines the UVC light required to penetrate the water and inactivate pathogens. Generally, a UVC unit should always follow a water filtration unit. Otherwise, higher UVC doses will be required due to higher levels of natural organic matter (NOM) turbidity and particulates in the water.

UVT can also vary between standard tap and pretreated waters, mainly due to the amount of chlorine in the water. With mercury lamps, chlorine in tap/pretreated water can consume a portion of the lamp’s disinfecting power. With LEDs, designers can select a more precise wavelength to minimize this impact. That, in turn, allows designers to balance the microbe response more closely with the UVT of the water and maximize overall system efficiency and results.

As shown in Image 2, an LED with a 265 nanometer (nm) peak will be 20% more effective at inactivating E. coli than an LED with a 275 nm peak (so a greater log reduction), while the impact of the UVT of tap water would only represent a difference of 6% (74% UVT at 265 nm vs. 80% UVT at 275 nm).

Establishing the UV Dose

Next, establish the optimum UV dose, which involves defining the microbe(s) and the corresponding disinfection levels and then establishing the LED power needed to achieve those levels—including the LED’s drive current and optical power at a specific wavelength.

Since most microbe disinfection data has been gathered using low pressure mercury lamps, designers will have to convert it to the LED wavelength. A UV dose equals the UV intensity (I) times the exposure time (t). The UV dose is measured in joules seconds per meter squared (J/m2) or millijoules seconds per centimeter squared (mJ/cm2); the UV intensity is measured in milliwatts per centimeter squared (mW/cm2); and the exposure time is measured in seconds.

Standards organizations like to identify and track target microbes or organisms deemed a public health concern. In practice, testing or validating a new POE system design using these target organisms would open a host of safety issues. As an alternative, designers can access and test their system with “good” organisms—Bacteriophage MS2, B. subtilis, etc.—that mimic the behaviors of the more harmful target organisms.

Establishing the Flow Rate

The focus then turns to the system’s water flow rate, which will directly impact the optical power needed for disinfection, the reactor tube dimensions, material and reflectivity, as well as the residence time of the microbe(s) in the flow cell.

This will determine the number of LEDs needed, where each one is placed, the driving current and how the LEDs will operate (continuous vs. pulsed). The goal is to deliver the ideal disinfection dose throughout the POE system’s lifetime.

The water flow rate—along with water quality, flow cell/water path and the pathogen(s) to be inactivated—directly impacts both the LED power requirement and the reactor size. The reactor size is also dictated by the space available for a particular design.

While more LEDs are typically required to treat POE system flow rates, transitioning from a POU design to a POE design is not a linear process. A lower flow POE system at 5-10 gallons per minute will typically employ a 20-watt mercury lamp. It is possible to replace this with approximately 1,200 milliwatts (mW) of UV power at 265 nm and match the performance with either 18 80 mW LEDs or eight 150 mW LEDs.

While eight 150 mW LEDs will produce less heat and provide more energy efficiency, increasing the number of 80 mW LEDs allows designers to benefit from LED redundancies and may increase overall system reliability.

If/when designers move to products with larger flow rates, reactor reflectivity and wall plug efficiency will be of greater importance as the ability to manage the thermals and power consumption will impact the overall performance and adoption of the system.