Commercial ultraviolet C (UVC) LEDs for disinfection are a known entity in point-of-use (POU) applications. The benefits of on-demand operation now makes them the technology of choice for these applications. In POU, UVC LEDs provide a more effective germicidal light source, more design flexibility and reduced cost of ownership for the end user.

In point-of-entry (POE) disinfection applications, mercury lamps remain the incumbent technology, but we are seeing a shift. As the performance of UVC LEDs has improved to meet the power and lifetime requirements of these higher flow systems, product engineers are developing new approaches to system design that leverage the full benefits of the LED across the entire life span of the product. Understanding end-of-life performance is key, as it is not the first gallon of water a user needs to be concerned about, it is the last.

Taking Cues From POU Systems

POU water disinfection systems, such as countertop or under-sink purifiers, can use UVC LEDs to design products that last up to 10 years without the need for annual lamp replacement. These systems take advantage of on/off cycling of LEDs for on-demand operation, eliminating the need for idle modes and improving energy efficiency.

A typical POU system will employ two to five LEDs to achieve adequate performance (e.g., National Sanitation Foundation [NSF] Class B) at a flow rate of 0.5 to 1 gallon per minute (gpm). The end-of-life point based on the product’s annual capacity and intended lifetime is typically 300 hours or less. This means that in general, most UVC LED-based POU systems will use less than 10% of the standard lifetime of the LED—effectively considering performance at L90 or higher for end-of-life specification.

POE Systems: Scaling Up for Whole-House Disinfection

POE systems typically handle higher flow rates, anywhere from 5 to 40 gpm. The most common residential whole home systems will operate at about 10 to 25 gpm and are often designed to meet NSF 55 Class B disinfection standards.

Although POE systems will use a larger number of UVC LEDs to meet this performance criteria, this increase is not linear with POU systems. Ten times the LEDs are not needed to achieve the same Class B performance at a 10x flow rate.

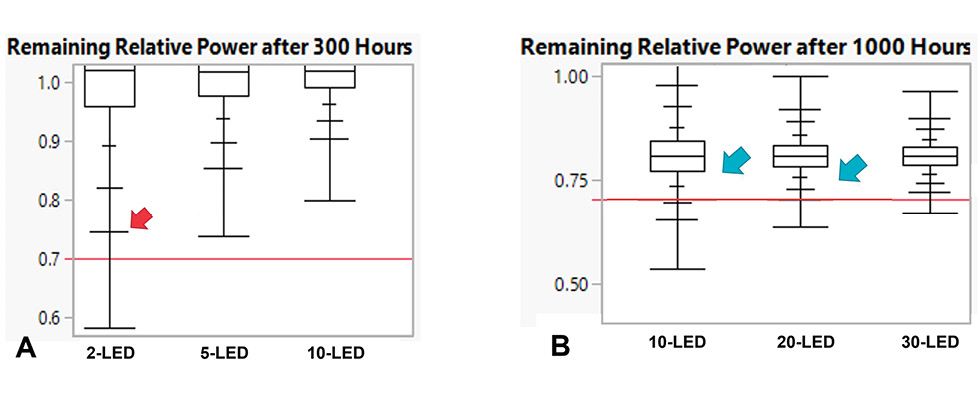

In POE, system designers will use more advanced thermal management to optimize LED performance, coupled with more sophisticated flow design and reflective materials to improve the disinfection dose. The data in Image 1 shows the dose performance for a POE system using 16 LEDs. The system can meet NSF Class B performance at 10 gpm. This meets the requirements for a standard residential system.

This data shows it is possible to meet Class B performance at higher flow rates with only about 10-20 LEDs—much lower than some modeling may show when switching from lamps to LEDs. This means that current UVC LED-based systems are suitable for higher flow systems earlier than many widely held assumptions, both from a performance and a cost standpoint.

But what about reliability over the lifetime of the system? Again, it is not necessarily how the system performs when it is installed. It is about ensuring the last glass of water is treated to the Class B standard. The expected lifetime for these systems is often in the range of three to six years, which with intermittent operation translates to approximately 3,000 hours at end-of-life.

Designing for Reliability & Performance

When looking at the system performance over time, the reliability of multi-LED assemblies needs to be analyzed—not just a discrete LED. This means understanding how to interpret the lifetime (L-value) and reliability (B-value) data based on an assembly of LEDs.

When reviewing reliability data for a POU design with a 300-hour end-of-life, designers should focus on data in the first few hundred hours. Similarly, for a POE system with a 3,000-hour end-of-life, the focus should be on data relevant to this timeframe—and based on the number of LEDs used in the design.

Evaluating the performance based on a printed circuit board (PCB) array with only 2-5 LEDs (a typical design for POU) is not relevant to a POE design. Let’s consider how to interpret reliability data based on two systems: a POU using 2-5 LEDs and a POE using 10-20 LEDs.

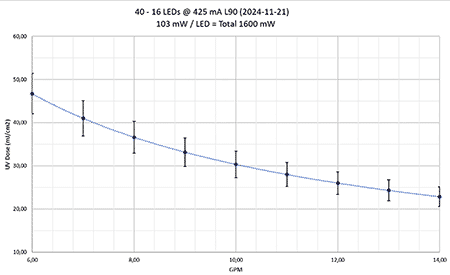

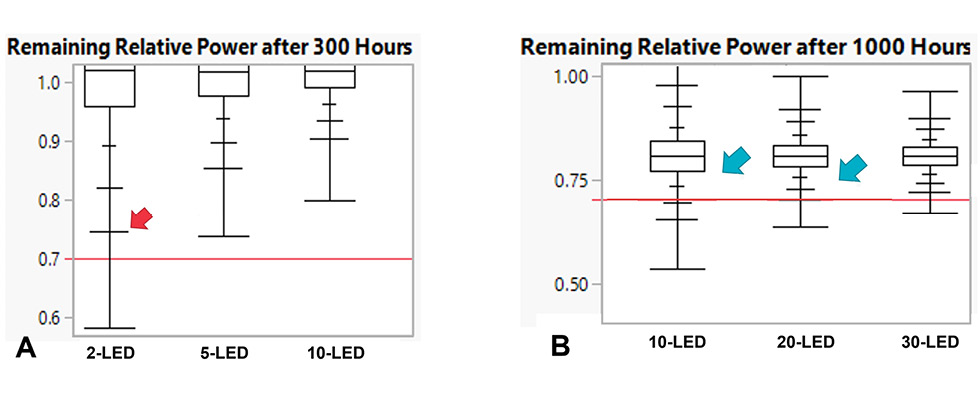

For illustration, the data in Image 2 shows test data for 1,300 LEDs that were stressed and tested for over 10,000 hours. Simulations were then created to randomly select LEDs from the population and model scenarios for designs using two, five, 10, 20 and 30 LEDs for a combination of 50,000 simulated systems.

Image 2A shows the behavior of the LEDs after 300 hours. Of the simulated 50,000 2-LED systems, 99% of them will have better than 70% of the initial power at 300 hours (L70B1). Image 2B shows the behavior of the LEDs after 1,000 hours. Of the simulated 10-LED and 20-LED systems, 95% have better than 70% of the initial power at 1,000 hours (L70B5).

These simulations show that when evaluating reliability, it is important to consider the entire LED assembly rather than individual devices. If a POE system designer considered the data for a 2-LED system at 1,000 hours, it would show a much higher B-value than a 20-LED system. This could lead the designer to potentially overengineer the system with too many LEDs for redundancy, increasing the system cost.

However, when considering the reliability data with a more appropriate 10-LED or 20-LED system, the system reliability is 95%. This system-level approach provides a more accurate picture of how the system will perform over its lifetime.

| Number of LEDs | 300 hrs | 1,000 hrs |

| 2 | L70B1 | L70B10 |

| 5 | L70B1 | L70B5 |

| 10 | L70B1 | L70B5 |

| 20 | L70B1 | L70B5 |

| 30 | L70B1 | L70B1 |

The transition from mercury-based UV lamps to UVC LEDs in water disinfection systems requires a new design approach to take full advantage of the benefits of the UVC LEDs. This shift has been seen in POU system design as more of these products have commercialized. POE designers are taking cues from the learnings in POU and are combining them with further sophistication in reactor design and LED operation to deliver disinfection performance at these higher flow rates. By better understanding LED reliability data and how it relates to the total number of LEDs, designers can better balance performance, reliability and cost.