How much can I expect efficiency to increase when a VFD is added to my pump?

Commonly, energy consumption and efficiency are referred to interchangeably with pumps, specifically when a variable frequency drive (VFD) is added to vary the speed of the motor and pump. In actuality, the addition of a VFD while keeping all else constant, will not change the pump efficiency (η) and will actually reduce the overall efficiency (ηOA).

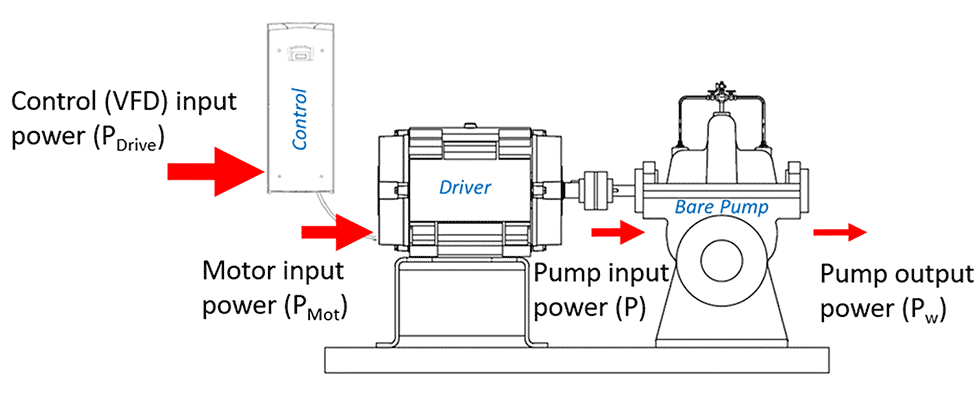

Represented in Image 1 and Equation 1, pump efficiency is the ratio of pump output power (Pw – function of flow rate and head) and pump input power (P), which are not affected by the VFD unless speed is increased or decreased.

Now, if we consider overall efficiency, which in Image 1 is the ratio of pump output power (Pw – small red arrow) and control (VFD) input power (PDrive – large red arrow), we can see the overall efficiency will decrease due to losses across the VFD, resulting in greater power into the VFD than into the motor. There will also be incremental increases in motor losses due to the VFD power, which are generally minor and not depicted.

The efficiency of VFDs is high so the losses are often modest (~3%), which can be greatly outweighed by system control efficiencies. The preceding discussion about reduced overall efficiency when adding a VFD however, does not mean power consumption will increase because the purpose of a VFD is to control the speed of the pump and change the operating point (head and flow rate), which will change the pump output power and input powers.

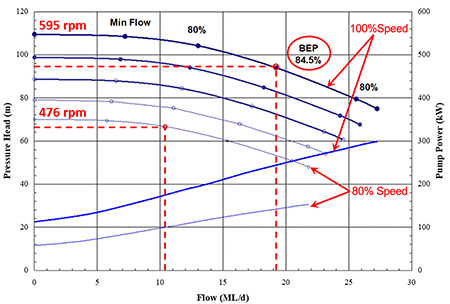

Examining Image 2 reveals how the pump performance (head and power versus flow) change with speed and why using VFDs to reduce speed often reduces power consumption, even if pump efficiency and overall efficiency decrease.

Image 2 depicts a variable speed pump system designed for a maximum flow rate of 19.1 million liters per day (ML/d) and 95 meters (m) of head at 100% speed, and a minimum flow rate of 10.4 ML/d and 66 m of head at 80% speed. The pump efficiency actually decreases from the best efficiency point (BEP) of 84.5% to the maximum design flow rate to 80% at the minimum design flow rate.

However, the pump input power in kilowatts (kW) decreases from about 245 kW to 100 kW. In contrast, if the system owner decided to use a control valve (instead of using a VFD to reduce speed) to reduce the flow rate, the system would operate at the 100% speed head point of 108 m (power = 175 kW) compared to 66 m (power = 100 kW) at 80% speed. This example illustrates that there is more to power consumption than pump efficiency.