Examine the average centrifugal pump fundamentals course. It assumes the pump is at or near sea level, and the absolute atmospheric pressure is presumed to be 34 feet of head. This assumption is a common and practical way to start the lesson, but what I later witness are students who did not receive practical exercises in real world situations. Even when the instructor offers the rare application example at some higher elevation, the student will often default to sea level assumptions. If you are sizing and selecting pumps for the Maldives, Holland, south Florida or Delaware, this is not an issue, but not every pump system is so lucky.

Real Life

Failure to properly size a pump system because of higher elevation requirements can be an expensive mistake. Many years ago, I designed a packaged transformer cooling system I knew would be shipped to Chile. I requested the site elevation above sea level (ASL) numerous times, but to no avail. The customer kept telling me elevation would not be an issue because the units would be installed in an underground mine over 1,000 feet below the surface of the ground. I had no other valid jobsite information.

Fast forward to solving the inevitable issue of unit nonperformance—even when 1,000 feet deep in the mine, the units were still 16,000 feet ASL. The user was lucky in this case, because there was no pump problem and we simply swapped out the fan motors with the next larger frame size. The user did not have to change breakers, starters, conduits or wire size.

An interesting side story is that 18 years later and less than a few miles from the aforementioned mine, I was again involved in troubleshooting a nonperformance issue, this time with a self-primer pump. Even at sea level, a self-primer cannot lift 40 feet. In a perfect world, ignoring friction and vapor pressure, it can lift 34 feet, but real-world factors make the actual lift closer to 25 feet. Even at 10,000 feet ASL, the maximum lift would be less than 14 feet for 68-degree water. I did not compute a realistic maximum lift for 17,000 feet ASL, but I estimate it was less than 8.5 feet.

If the pump systems you design, build and sell all end up in your backyard and that is somewhere below 1,000 feet ASL, then your main concerns are the maximum lift, net positive suction head available (NPSHa) and submergence.

Sea Level & Atmospheric Pressure

So we are all on the same page when it comes to the subject of elevation, science has agreed to use mean sea level as our datum point. At sea level, the atmospheric pressure under average conditions is 14.696 pounds per square inch absolute (psia), which we typically round off to 14.7. The 14.7 psia converts to 33.947 feet (multiply by 2.31 for ambient temperature water), and we normally round that to 34. (Note that for NPSHa calculations, right or wrong, I round down to 33 feet.) For the atmospheric pressure at sea level in the metric system, we use 760 millimeters (mm) of mercury (Hg) or 1,013.25 millibar.

Effects on the Pump

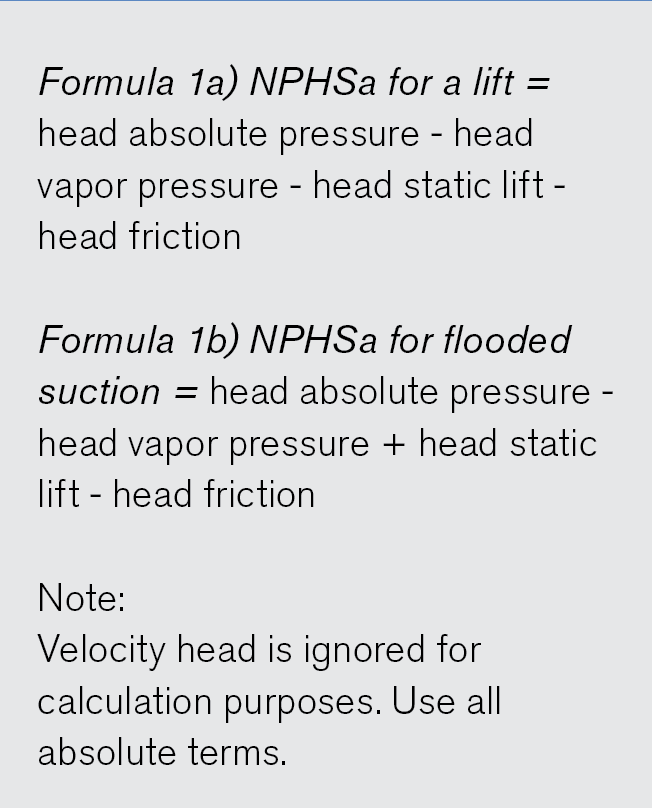

The biggest pump issue with an increase in elevation is the reduction in NPSHa. Insufficient NPSH will create cavitation, performance issues and physical damage. From the NPSHa formula, the factor directly affected is the head of absolute pressure (see Formulas 1a and 1b). What was 34 feet of absolute head from the air pressure at sea level can quickly become 23 feet at 10,000 feet ASL. To the uninitiated, this decrease of 11 feet may not seem like much, but in a world where a 1-foot margin can make the difference between success and failure, it is important.

Keep in mind that the gauges used to measure pump pressure will also need to be corrected to the elevation.

Combustion Systems & Engines

If the pumps you supply are associated with a combined heat and power system (CHP), the change in elevation (going up from sea level) will affect the performance of the entire system due to the “power to heat” ratios that are directly affected by the higher elevation.

Combustion engines such as gas, diesel and propane, even with turbo chargers, will be derated as elevation increases. Gas turbines, even though not reciprocating engines, still have derate factors with elevation. A 100 horsepower (hp) engine at sea level is not 100 hp at 5,000 feet ASL. Most engine manufacturers test and adjust the engine rating to a datum referenced at 300 feet (90 meters) ASL in accordance with the Society of Automotive Engineers (SAE) J1349 Certified Power Standards. Any operation at elevations above this 300-foot elevation requires engine derate factors, typically 3% per every 1,000 feet (305 meters) of change.

Consult with your engine supplier for details and make sure they know the defined duty cycle, that you require “continuous” power and that you are driving a centrifugal pump. Become technically familiar with the expression “brake mean effective pressure,” which is an empirical measure of the load imposed on the engine. Another way to think of this term is that it is the brake horsepower (bhp) required at the output shaft of the engine (coupled to the pump) and is indicative of an engine’s capacity to produce the proper amount of power over the full speed range. There are other important measures of engine performance; this is just one of many.

Centrifugal pump shafts are typically designed and rated for continuous torque, as experienced when driven by an alternating current (AC) induction motor. The pump manufacturer will design for a given safety factor and an allowable brake horsepower per 100 rotations per minute (rpm) rating limit. Combustion engines are intermittent torque drivers; consequently, the allowable pump shaft rating will be less when driven in this manner. The derate will vary with manufacturer size and model. Typical derates can be in the area of 20%-40%, depending on the speed and the manufacturer. A slower speed application would have a higher amount of derate due to the horsepower to torque to speed relationship.

Electrical

Because heat transfer capabilities are reduced at higher elevations due to lower air density, motors must be derated for elevation changes. Typically, motors are fully rated (per nameplate) up to 3,300 feet (1,000 meters) ASL. For every 330 feet (100 meter) increase in elevation above 3,300 feet, the motor is derated by 1%. See NEMA MG 1-14.4.3 for details. For standard design motors, most manufacturers will also express a maximum elevation for the equipment.

Should your application be variable speed, check with the manufacturer to ensure the equipment is rated not just for the lower speeds and higher torques but also for the reduced cooling capacity.

Because of the lower air density at higher elevations, the insulation air gaps on motors and related equipment (starters and drives, for example) can be compromised at higher elevations. At sea level, the air gap successfully acts as an insulating dielectric, but as elevation increases, the gap resistance is reduced. The higher elevation also affects the tripping properties of thermal relays. In a similar way, the heat transfer capabilities of the equipment are also compromised. Refer to the equipment manufacturer and “Paschen’s Law” for more specific information regarding the effects due to operations at higher elevations.

Geography

It pays to be informed regarding pump site elevation. You may be surprised by the elevation in some parts of the world. We all know that western Colorado is at high elevations (perhaps thanks to John Denver’s song). Much of the region is well above 5,000 feet. Many people think of Hawaii as being close to sea level (it’s the beaches), but if you were selling pumps to the Mauna Loa observatory on the big island, the elevation there is 11,135 feet. There are hundreds and perhaps thousands of pumps in service near the Dead Sea, which is 1,412 feet below sea level, but not too far away, the elevation in the Golan Heights is over 7,000 feet ASL.

Altitude vs. Elevation

Proper English is in order. There is a subtle difference between the words altitude and elevation. Both are typically measured (vertically) up from the mean sea level, but the term altitude is reserved for situations where your feet are not on the ground, such as in an airplane or if you are base jumping. When discussing the distance above sea level, altitude is the correct word if you are in an airplane, and elevation is the correct word for standing on the ground, perhaps on the side of a mountain. If there is an altimeter involved in the situation, chances are the correct word is altitude.

Closing

Heard from a friend: Perhaps little to nothing to do with pumps per se, but it still remains as good advice. The lower air pressure at higher elevations causes the human body to absorb alcohol faster into the bloodstream. Consequently, the deleterious effects of alcohol on the brain are markedly increased with elevation. John Denver already knew.

References

- Hydraulic Institute Standard 14.3

- NEMA MG 1-14.4.3

- SAE J1349

- NFPA 37

- IEC Standard EN60947-1

- National Oceanographic and Atmospheric Administration (noaa.gov)(Sea Level)

- NASA (nasa.gov)(Sea Level)

- Pumping Station Design 3rd edition, Garr M. Jones et al

- ASHRAE Handbook 2024, HVAC Systems and Equipment