The Wastewater Association of Rheinfelden-Schwörstadt operates the wastewater treatment facilities in Schwoerstadt and Rheinfelden-Herten, Germany, as well as several rainwater overflow basins. The wastewater treatment facility in Rheinfelden-Herten has been in operation since 1980 and has been converted and reconditioned in recent years to meet the latest technical standards. This wastewater treatment facility now satisfies the highest requirements, and with a population of about 47,000, has reached a size that also guarantees sufficient disposal capacity for future generations. The Rheinfelden wastewater treatment facility is the larger of two facilities of the Wastewater Association of Rheinfelden- Schwoerstadt, purifying 4,000 cubic meters (m3) of wastewater a day in dry weather and up to 25,000 m3 in wet weather. For ventilating the aeration channels, the facility relies on rotary lobe blowers, which provide the necessary injection of oxygen.

Image 1. Water treatment aeration channels at this facility in Germany receive oxygen from four blowers. (Images courtesy of Busch Vacuum Pumps)

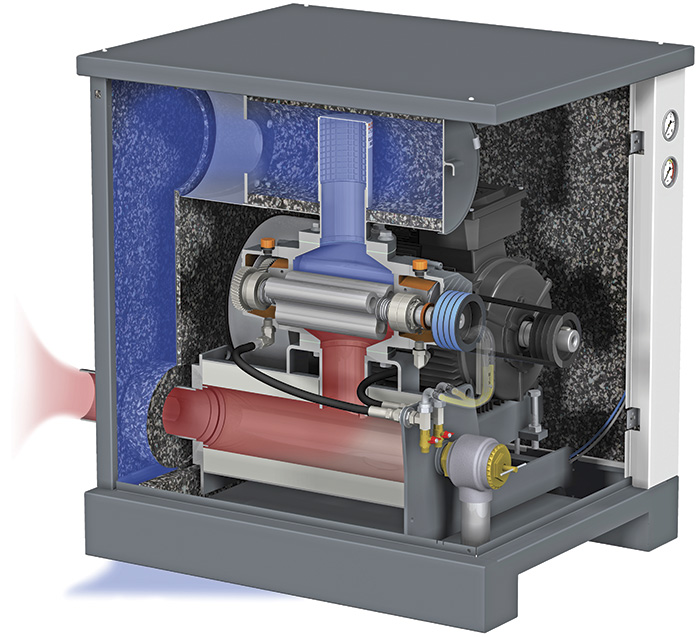

Image 1. Water treatment aeration channels at this facility in Germany receive oxygen from four blowers. (Images courtesy of Busch Vacuum Pumps) Image 2. A look inside a rotary lobe blower

Image 2. A look inside a rotary lobe blower