How is pump bearing housing vibration measured?

Acceleration transducers (accelerometers) are typically used to measure vibration on stationary components such as bearing housings, but transducers that measure velocity are available. Depending on the reason for the measurement, and frequency range of interest, the acceleration signal may then be integrated to velocity or double integrated to displacement.

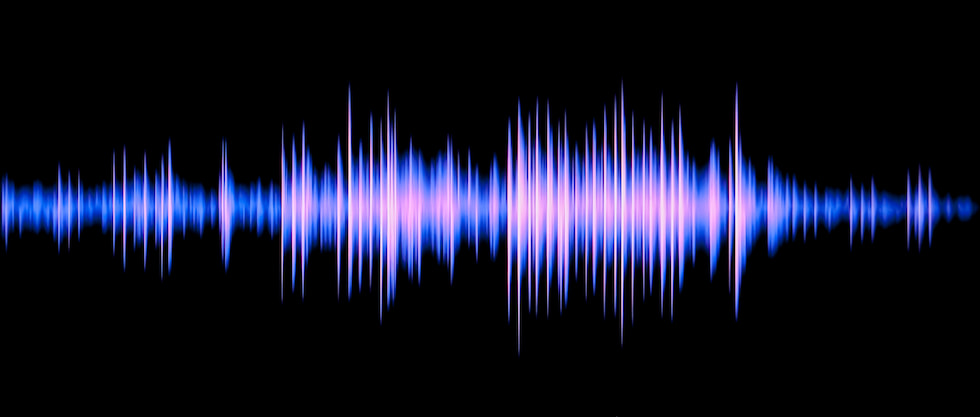

Image 1. Typical time waveform showing peak-to-peak (0.306), 0-peak (0.155), and RMS (0.065) values. (Images courtesy of Hydraulic Institute)

Image 1. Typical time waveform showing peak-to-peak (0.306), 0-peak (0.155), and RMS (0.065) values. (Images courtesy of Hydraulic Institute)Measurements are made in the time domain and then processed and filtered to show the level of vibration occurring at discrete frequencies. The time domain data can be useful in understanding impacting forces that may be random, such as cavitation, or periodic impacts such as a broken gear tooth.

The time domain data is then generally processed and displayed in a frequency spectrum that identifies vibration at specific frequencies.

This is convenient to understand what vibration is occurring at known discrete forcing frequencies or impeller vane passing frequency. Image 4 shows a frequency spectrum with orders of the shaft frequency called out.

For the purpose of acceptance testing per ANSI/HI 9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values, the measurements are integrated in a circuit to determine the overall root mean square (RMS) vibration. For speeds above 600 rpm, the sole measurement quantity measuring the vibration of stationary parts associated with bearings of rotodynamic pumps is velocity in millimeters per second RMS or inches per second RMS.

Image 2. Frequency spectrum showing discreet forcing frequencies and high frequency noise.

Image 2. Frequency spectrum showing discreet forcing frequencies and high frequency noise.The instrumentation should measure the RMS vibration velocity for a minimum frequency range of 5 hertz (Hz) to 1,000 Hz. For speeds of 600 rpm and below, the peak-to-peak displacement vibration on bearing housings should also be measured, and the instrumentation should cover a minimum frequency range of 2 to 1,000 Hz. ANSI/HI 9.6.4 specifies locations for the acceptance testing.

The transducers should be located approximately at the center of the radial bearing location on bearing housings or the motor mounting flanges of vertical pumps. Transducers must not be on flexible panels, nameplates or motor end covers. For more information, refer to ANSI/HI 9.6.4.

Read more HI Pump FAQs by clicking here.