Virtual power plant gives utilities the upper hand

National Instruments

01/03/2018

Utility companies are asked to manage the grid safely, reliably and affordably—a challenging task considering the lack of control over anything on the consumer side of the meter. Utilities typically do not control when loads come on and off the grid. They also do not control consumer-owned solar equipment —commercial buildings, parking lots, residential—that is connected to the grid at an ever-increasing pace. Despite this, utilities balance demand with generation in real time.

Image 1. Hardware installed at participant building sites gives utilities real-time control of customer-owned assets like HVAC, lighting, back-up generators and solar arrays. (Images and graphics courtesy of National Instruments)

Image 1. Hardware installed at participant building sites gives utilities real-time control of customer-owned assets like HVAC, lighting, back-up generators and solar arrays. (Images and graphics courtesy of National Instruments)Bridging the Gap at the Meter, Using IoT

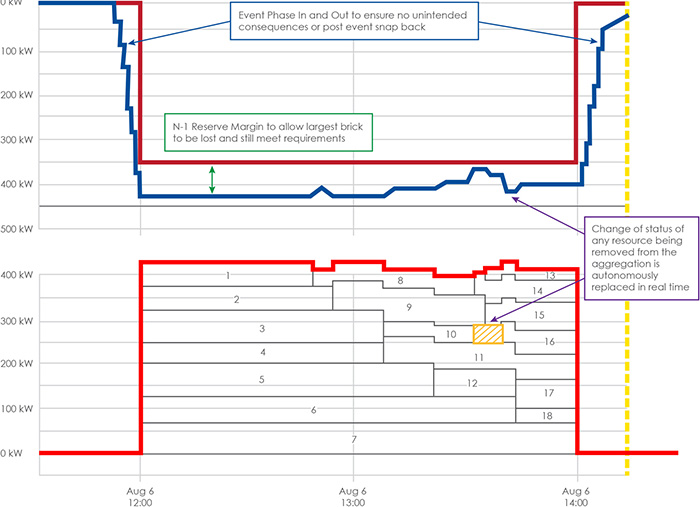

To help compensate for lack of control and real-time visibility, grids are built to manage peak conditions that occur only about 5 percent of the time. This “state of today” represents the most efficient, safe and reliable way given technology at the time of construction, but innovative companies are using Internet of Things (IoT) technologies to bridge the gap that exists at the meter between utility companies and energy customers to optimize grid utilization. Innovari is one such company using IoT technologies and utility expertise to improve how energy is produced and consumed. The proliferation of smart and connected “things” in the Industrial Internet of Things (IIoT) provides opportunities for increased performance and lower costs. By implementing intelligent edge nodes distributed across the grid and cloud-based analytics, companies working in the IIoT space are able to help utilities improve overall system utilization and save costs. One IIoT platform solution uses machine learning, “big data” analytics, proprietary optimization routines, and distributed measurement and control hardware to deliver generation quality capacity that can address grid demand. The IIoT company’s grid-edge hardware attaches to participant buildings to monitor and control various elements of the building that impact the grid such as heating, ventilation and air conditioning (HVAC) systems, lighting, back-up generators and solar arrays. The hardware uses single board controllers, designed for intelligent IoT edge nodes, to calculate various features of energy consumption along with real-time, two-way communication to the cloud analytics component of the platform. Typical participant buildings include big box retailers, shopping malls, hotels, universities and larger office buildings. As a demand-based event occurs on the grid, utilities can request a specific amount of load to be shed for a specific length of time to balance the grid. The IIoT platform solution’s cloud algorithm surveys all the circuits under control and turns off appropriate circuits at the right time and in the right order to predictably give the utility the exact load drop requested. This ability to shed load with the same level of control as adding capacity with a power plant gives utilities another tool to help manage challenging demand-based grid events—effectively a virtual power plant. Figure 1. Control of multiple customer-owned assets helps create a virtual power plant utilities can use to mitigate demand-based events.

Figure 1. Control of multiple customer-owned assets helps create a virtual power plant utilities can use to mitigate demand-based events.