State and federal requirements increase the need for pump monitoring and control.

Intelligent pumping can simply be defined as the combination of a pump and a VFD with digital control capability. As this trend has increased, new implications or possibilities are available for

- Energy management

- Remote condition monitoring

- Remote systems control

In response, intelligent pump systems are expanding to include wireless control and monitoring capabilities. Although the initial installation costs can be high, such systems provide users with the ability to access real-time operating data on their pumping equipment, which offsets the higher initial costs through reduced unplanned downtime and improved predictive maintenance plans. The added benefits of wireless pump control and monitoring systems are apparent when reviewing the current challenges faced by pump system end users. Several additional benefits are outlined in Figure 1.

Figure 1. The benefits of wireless asset management

Historically, pumping system automation has often been addressed as a one-off engineered solution based on customer needs and architectural/consulting engineering specifications.

A project would be identified, a specification created, and then it would go out to bid. The low bidder (a mix of system integrators, pump system manufacturers, and pump OEMs) would be awarded the project and design/build the system to the specification requirements.

Because of time, money, application and automation knowledge and governmental regulatory changes, many of the advanced control and energy management strategies were not implemented or even considered.

Water & Wastewater Monitoring

Water, wastewater and storm water agencies are looking for simplicity, configurability, energy management and advanced pumping schemes, in a pump control package.

However as technology has evolved and more importantly become increasingly user friendly, facility operations and management have demonstrated the desire to take advantage of the latest technology available—such as Internet communication for monitoring and control, WiFi communications, smartphone interface to their pump controller for alarms and remote control and configuration. They seek a flexible, off-the-shelf device to reduce their automation cost, startup time, implementation time and operator training.

Changing state and local government requirements for water and wastewater monitoring and control have increasingly burdened municipalities and industry alike to increase systems' monitoring capabilities. Facility operations and management want a product that will give them uninterrupted data monitoring and gathering with “no holes in the data.”

According to the EPA, over fifty percent of the transient water systems in the U.S. do not have remote monitoring and control of their pumping assists. These agencies are looking for off-the-shelf products that give them all the real-time SCADA system benefits but not the automation cost and complexity.

The Solution

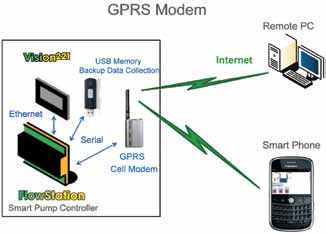

A flow station smart pump controller is available that has a built in Web server that publishes Web pages to a PC or smartphone allowing the operators or operations manager to receive data, alarms and SMS text messages regarding the health and operation of the pumping assets. See Figure 2.

Figure 2. The flow station smart pump controller

The USB memory stick collects run time data, flow history and power quality information and stores it so that no data is lost if communications fail.

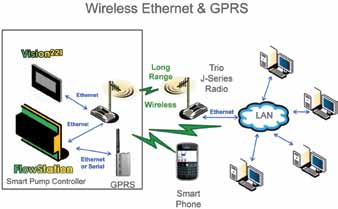

Operators need products that can expand with their system needs—such as the architecture shown in Figure 3, allowing for redundant commutations via long-range wireless Ethernet radios. These radios are used as primary communications, and GPRS communications are a backup communications link for those pumping assets that must be monitored at all costs.

Figure 3. Multiple communication methods are available.

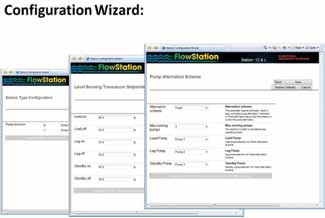

End users are also looking for configuration and implementation simplicity. The use of configuration wizards (as shown in Figure 4) with this control system allows the operations personnel to set up pumping assets, communications, data storage, etc., without having to know how to program code. Simple instructions with explanations of each set in the process allow the operations personal easy setup of the controllers.

Figure 4. Simple set up is possible using configurations wizards

Summary

As the needs for energy efficiency, real-time access to equipment data and an intelligent control approach—driven by requirements to monitor and control pumping systems located in multiple, sometimes remote geographies—continue to grow, users will increasingly demand SCADA-based solutions. As these solutions evolve and become increasingly intelligent and simpler to integrate, they will become an increasingly vital component to developing more efficient and reliable production processes for pump end users. In fact, Frost & Sullivan anticipates that the market for real-time mobile asset tracking and preventive maintenance monitoring will increase five-fold by 2020.

Pumps & Systems, September 2011