Pumps are often touted for their high-capacity flow rates, and this is important in many applications such as bulk transfer, gland seal flushing and saltwater disposal. For metering applications where precision and accuracy take precedence, just the opposite—low flow rates—are often required. Since it is metering, a pump should also meet the American Petroleum Institute (API) 675 standards for steady-state accuracy (plus or minus 1 percent), linearity (plus or minus 3 percent), and repeatability (plus or minus 3 percent). Low flows are required for many processing and manufacturing applications, including many in the water and wastewater industry. These can include mixing polymers for water treatment and dosing phosphates, ammonia and other chemicals in boiler feed; metering methanol or corn syrup for wastewater nitrification; and general chemical injection. At least one triplex metering pump with a flow rate range of 0.06 gallons per hour (gph) to 8 gph while exceeding API 675 performance standards is available. This pump can deliver flows at discharge pressures up to 3,500 pounds per square inch (psi) for metallic pump heads and 350 psi for nonmetallic pump heads (depending on material).

Image 1. Wastewater aerial (Images courtesy of Wanner Engineering Inc.)

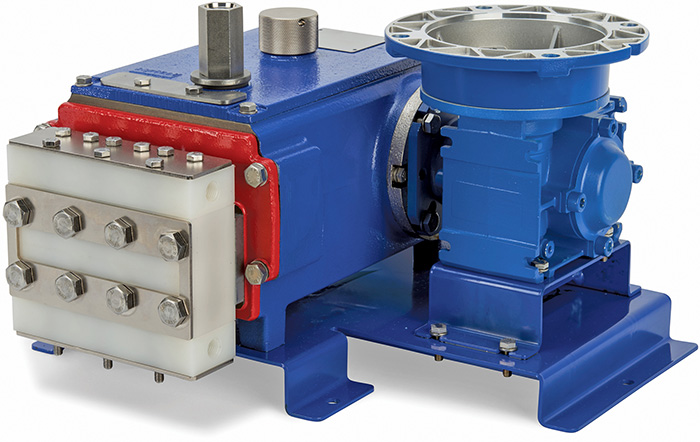

Image 1. Wastewater aerial (Images courtesy of Wanner Engineering Inc.) Image 2. Triplex metering pump

Image 2. Triplex metering pump Image 3. Metering control panel

Image 3. Metering control panel