Hydraulically actuated and critical service diaphragms enhance safety and uptime.

11/18/2015

More than 60 million tons of polyethylene are manufactured each year, making it the world's most pervasive plastic. It is used to make bottles, buckets, packaging and dozens of other products that we see and touch every day. The feedstocks used to make plastics are crude oil and natural gas, which are broken down into smaller components, such as naphtha, ethane and propane (among others). Larger hydrocarbons are further separated into smaller molecules through a complex cracking process that uses temperature, pressure and chemical additives to create the building blocks needed to transform feedstock into plastics.

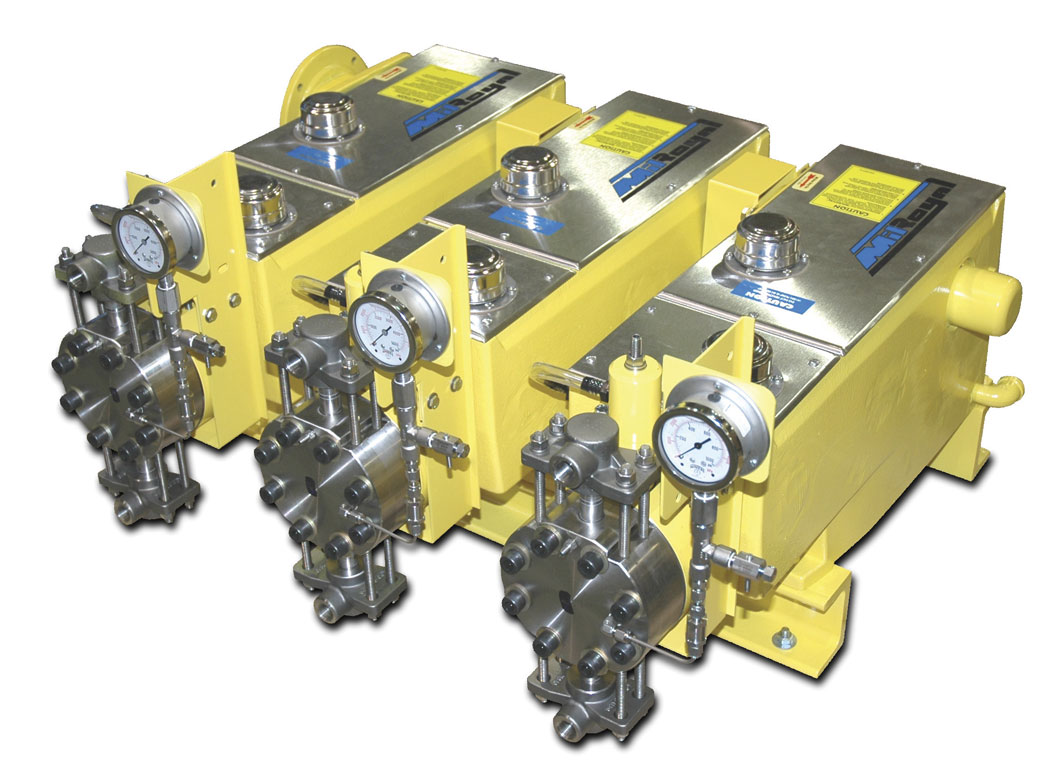

Image 1. These metering pumps are designed for high-pressure, critical chemical processing. (Images courtesy of Milton Roy)

Image 1. These metering pumps are designed for high-pressure, critical chemical processing. (Images courtesy of Milton Roy)Pump Accuracy

Although metering pump accuracy is important in any industry, it takes on a different meaning in critical chemical processing. As a comparison, consider metering pumps used for some other industries where small tolerances in the volume of chemicals rendered will still produce the desired effect. Consider the same scenario with metering chemical catalysts to make plastics. Hydrocarbons changing state do not pass from a single starting point to a single end point. Instead, they follow a dynamic continuum where pressure and temperature variations, or different volumes of catalysts, can cause feedstocks to transform into any number of elements. Metering out too much or too little can result in an explosion, or it can render a product that does not resemble the desired plastic. Either way, it is paramount to dose the precise amounts of catalysts at precisely the right time to produce the desired product. In chemical processing, accuracy goes beyond quality control. It also affects the bottom line. Because chemical plants run continuous operations, actions need to be done right the first time. It is difficult and, in some cases, impossible, to repeat the setup and start over. Errors in one part of the process create ripple effects elsewhere that cost time and money. For all of these reasons, metering pumps must be designed to deliver ±1 percent steady state accuracy with 100 to 1 turndown ratios and capacity that can be adjusted by manual controls, variable speed drives, and electronic or pneumatic actuators. Image 2. The hydraulically actuated diaphragm operates with equal pressure between the hydraulic and process fluids, resulting in low stress on the moving parts which leads to better pump performance and longevity.

Image 2. The hydraulically actuated diaphragm operates with equal pressure between the hydraulic and process fluids, resulting in low stress on the moving parts which leads to better pump performance and longevity.