In the intricate world of meat rendering, efficiency, precision and sanitation are key. This industry transforms animal by-products into valuable materials like fats, proteins and meat meals. Traditional heating methods, such as indirect heat exchangers or spargers, are standard, but these systems often have issues like slow heating cycles, energy inefficiency and maintenance needs. Direct steam injection (DSI) heaters offer an alternative that allows facilities to streamline their processes, enhance sanitation and reduce costs. This article will explore the role of DSI heaters in improving meat rendering operations and how they can benefit high-value rendering streams.

The Basics of the Rendering Process

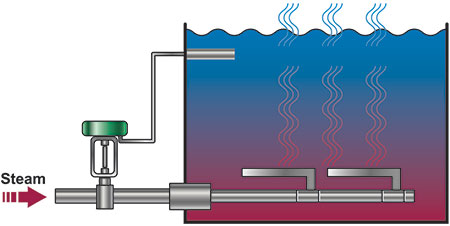

Rendering transforms raw materials or by-products from the harvest process—such as fatty trimmings, bones and low-value organs—into valuable products like fats, oils and greases. The process begins by grinding the raw materials to increase their surface area, which improves the efficiency of fat, oil and grease extraction. The ground material is then heated in vessels like jacketed tanks or dissolved air flotation (DAF) systems. This heating causes low-density fats to separate from higher-density water and solids, allowing the fats to float to the surface. These “skimmings” are collected and reheated in a melt tank before undergoing further processing in a centrifuge or similar separation technology. The result is high-quality fats, oils and greases ready for refinement or distribution.

In addition to these standard outputs, certain high-value by-products require specialized heating to maximize their value and maintain quality. By-products such as brown grease, lard, tallow, gelatin and meat and bone meals demand precise temperature control to meet stringent standards for purity and sanitation.

DSI technology excels in these applications by providing consistent temperatures and efficient processing, outperforming traditional methods. Optimizing these high-value streams with DSI ensures superior product quality while enhancing sustainability and operational readiness. The efficiency and adaptability of DSI technology play a critical role in modern rendering, ensuring the production of valuable by-products in a streamlined and environmentally responsible manner.

Why Heating Matters in Rendering

Heating is fundamental to several rendering stages to optimize separation, particularly in liquefying fats. Here is why it is essential to heat skimmings before separation and how DSI heaters improve this process:

- Enhanced separation efficiency: Heating liquefies fats and oils, lowering viscosity and aiding smooth flow through separators, which prevents clogs or blockages.

- Better microbial control: Heating helps manage the microbial load, critical in fats destined for human consumption, where sanitary standards are more stringent.

- Increased product yield: Liquefying fats increases the volume of recoverable material, maximizing the value derived from each batch.

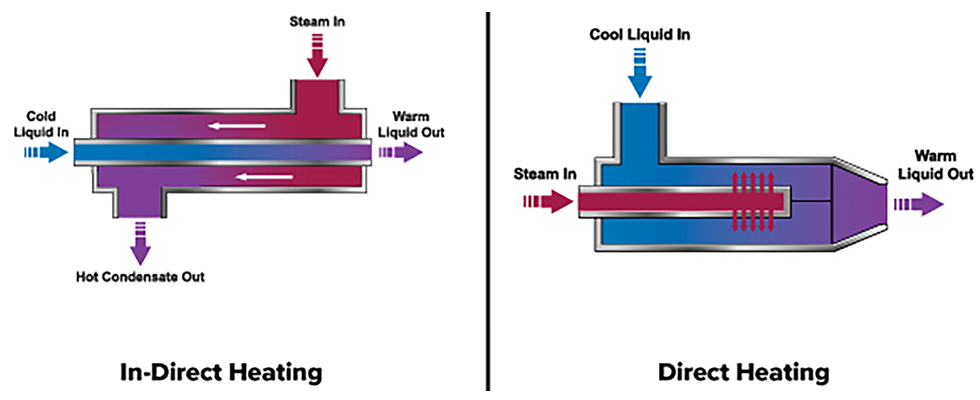

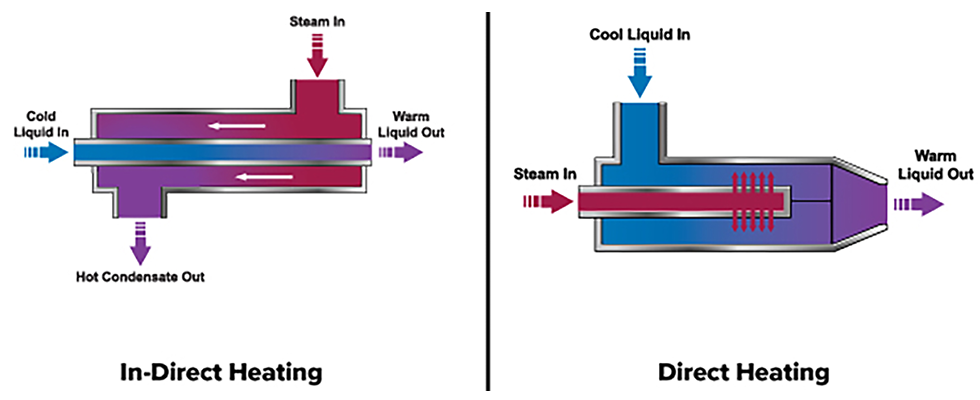

Traditional vs. DSI Heating

Traditional melt tank heating systems, like jacketed vessels, heat exchangers or spargers, have limitations:

- Slower batch heating: Heating large batches using indirect methods takes longer, delaying processing times.

- Temperature inconsistencies: Steam jackets or spargers can lead to uneven heating, risking burnt fat on the tank surfaces.

- Space-consuming equipment: Melt tanks take up valuable floor space, potentially limiting production flow.

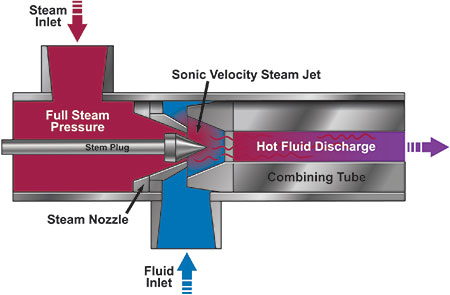

DSI helps bypass these limitations by allowing continuous inline heating. Steam is directly injected into the fluid process, reaching target temperatures instantaneously.

Advantages of DSI in Meat Rendering

- Rapid uniform heating: With DSI, steam is injected directly into the fluid, achieving instant, even heat. This eliminates the heat loss typically experienced with jacketed tanks, ensuring the entire batch reaches the optimal temperature for efficient and thorough separation.

- Precise temperature control: Rendering processes depend on tight temperature control to maintain product quality. Overheating can spoil valuable fats, while underheating can impair separation efficiency. DSI heaters provide direct steam injection, allowing real-time adjustments to reach and maintain precise temperatures.

- Energy efficiency: Indirect heating systems, like heat exchangers, can suffer from heat transfer losses, as energy is lost through intermediary surfaces. DSI heaters, however, can operate at nearly 100% thermal efficiency because the steam energy is directly transferred to the fluid. This saves energy and reduces operational costs and greenhouse gas emissions.

- Reduced maintenance needs: Heat exchangers and spargers can require frequent maintenance due to scaling, fouling or mechanical wear. With fewer moving parts, DSI heaters experience less wear and need less frequent service, minimizing downtime and reducing costs.

- Enhanced sanitation and food safety: DSI systems inject steam—a natural sterilizing agent—directly into the product, greatly improving sanitation. By eliminating intermediary surfaces, DSI heaters reduce bacterial growth potential and make meeting industry sanitation standards easier. This not only enhances the safety of the final product but also ensures its quality.

- Compact design and flexible integration: DSI heaters take up less space than traditional systems, and their drop-in spool design allows them to be placed almost anywhere in the line. They do not have to be restricted to the melt tank, allowing for flexibility in facility layout and process flow.

Environmental Sustainability

With sustainability taking center stage across the food industry, DSI heaters can help facilities become more environmentally responsible, leading to:

- Lower fuel consumption: DSI’s energy efficiency translates to reduced fuel usage, lowering carbon emissions.

- Minimized water waste: Precise control minimizes product waste during rendering, conserving valuable water resources.

- Reduced chemical usage: The consistent temperature control of DSI allows additives to be used more efficiently, lowering overall chemical usage and reducing environmental impact.

Future-Proofing Meat Rendering

The transition to DSI heating represents a move toward more efficient, flexible and sustainable practices within meat rendering. DSI technology is adaptable and can meet current and future production needs. As the industry faces growing pressure to enhance sustainability and minimize environmental impact, DSI heaters provide a pathway toward greener, leaner and more productive operations, ensuring the rendering facility is future-proofed.

With DSI’s adaptability, efficiency and environmental benefits, this technology supports the industry’s ongoing push for better processes and more sustainable practices. Modernizing heating systems allows facilities to maintain high standards while contributing to a cleaner, more efficient industry.