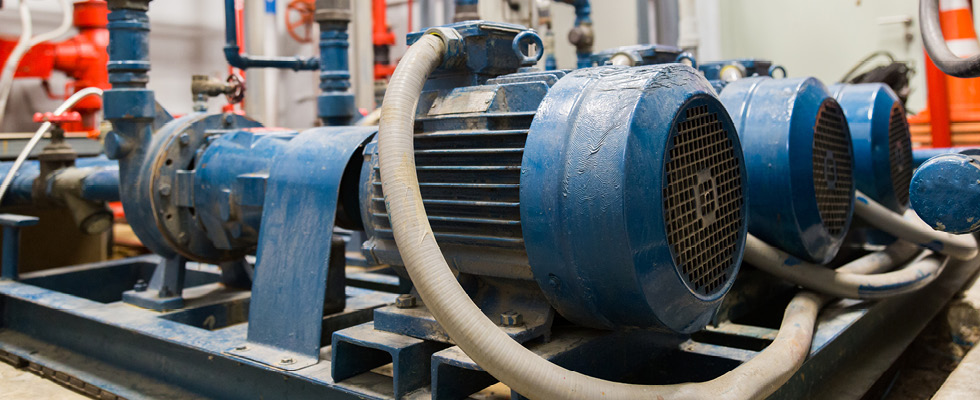

When every second of operational uptime counts, the concept of predictive maintenance for pumps with condition monitoring emerges as a game changer. Predictive maintenance is a strategy that employs sensors and analytics to foresee and fix potential pump problems before they escalate into costly shutdowns. Let’s delve into the nuts and bolts of this approach and shed light on why understanding and implementing it could be the key to keeping operations smooth and uninterrupted.

What Is Predictive Maintenance for Pumps Using Condition Monitoring?

Predictive maintenance for pumps using condition monitoring involves using sensors and data analytics to track the real-time performance of pumps, such as vibration patterns, temperature changes and electronic signatures. This approach allows for smart, timely maintenance decisions to prevent unexpected failures and downtime.

Distinguishing predictive maintenance from reactive and preventive maintenance

Predictive maintenance distinguishes itself from reactive and preventive maintenance by its proactive approach. Instead of waiting for equipment to fail (reactive) or scheduling maintenance at fixed intervals regardless of actual need (preventive), predictive maintenance uses intelligent sensors to monitor equipment in real-time. This allows for the early detection of potential issues, often days or months in advance, enabling maintenance actions to be taken just in time to prevent failure. This strategy relies on data analysis and sensor technology to optimize the maintenance of assets, ensuring they receive attention only when necessary.

Key Components & Technologies in Predictive Pump Maintenance

In the world of predictive maintenance, there are many high-tech players. There are sensors that track everything from vibration to temperature and wireless communication solutions that send that data flying to the places it needs to go.

The role of condition monitoring in predictive maintenance

Condition monitoring is the heart of predictive maintenance. Imagine tying a sensor to every part of the pump that could tell the user how it is feeling. It is like giving the pump a way to speak up when it is not feeling great. This system keeps an eye on how the pump is doing at all times, alerting the user to the most minuscule changes that could mean trouble is brewing. It leverages machine learning to turn mountains of data into practical advice for maintaining pumps, ensuring they are in optimal condition and ready to keep on pumping without costly interruptions.

Common Pump Failures & the Importance of Early Detection

Some may think pumps fail without warning, but they are actually quite chatty before giving up. Knowing the whispers of a failing pump can save users from a loud, costly breakdown. A pump in distress might cling to life for a bit, but left unchecked, it is a disaster waiting to happen. This is where detecting the early cries for help becomes crucial and can be the difference between a quick fix and a full-on production stop.

Mechanical failure symptoms in pumps

Mechanical failure symptoms include noticeable vibrations, rattling from loose components and leaks. Additionally, worn-out bearings may produce grumbling noises, and a failing pump seal may result in drips, indicating the need for maintenance. Recognizing these symptoms early can prevent operational disruptions and costly repairs.

Fluid dynamics issues leading to pump failure

Fluid dynamics issues, such as cavitation caused by a pump working too hard, can lead to pump failure. Cavitation occurs when vapor bubbles form and collapse inside the pump, causing damage similar to being struck by tiny hammers.

Incorrect flow rates, either too high or too low, can also strain the pump excessively. These issues are akin to forcing a swimmer to race with weights attached, ultimately leading to failure. Proper management of fluid dynamics is crucial to prevent overstraining and ensure the longevity of pump systems.

Early indicators of failure in pump systems

Early indicators of failure in pump systems include unusual noises such as rumbling, whining or screeching along with elevated temperatures, similar to a fever indicating underlying issues. Recognizing these signs early can prevent significant damage, making them like smoke alarms for pump health and allowing for timely intervention to avoid more severe problems.

Selecting the Optimal Condition Monitoring Tools

Choosing the right tools to monitor pumps is like picking the best guardians for equipment. They need to be sharp, vigilant and versatile enough to cope with the unexpected. There is a maze of options out there and finding tools that can spot the faintest signs of a pump’s cry for help will set users on the path to maintenance and operation nirvana.

Vibration monitoring technologies for pump health

When it comes to catching a pump having trouble before there is a real problem, vibration monitoring tech is a user’s go-to detective. Imagine having a sensor so sensitive it picks up on the secretive chatter of misalignment or a bearing planning its farewell. These devices measure the shakes and shudders that might spell trouble, allowing users to leap into action. It is all about transforming vibrations into valuable data that whisper the secrets of a pump’s inner life.

How advanced sensors and IMUs play a role in condition monitoring

Advanced sensors and inertial measurement units (IMUs) are the spies in the world of pump maintenance. They take on the sneakiest of tasks—capturing the unseen twitches and turns of machinery. With absolute accuracy, these gadgets measure the tilt and thrust of pumps, revealing secrets even the most reliable eyes might miss. They are the special agents that track every move, ensuring nothing goes unnoticed and that every potential issue is flagged long before it becomes a mission-critical fiasco.

The advantages of wireless vibration sensors in pump monitoring

Wireless vibration sensors are the ninjas of pump monitoring. They slip into tight spaces, stick to their posts without a fuss and send intel back without a single wire in sight. With their stealth, they are revolutionizing pump monitoring by allowing flexibility in placement and real-time data transmission.

They shrink downtime by providing immediate alerts, and since they are so easy to install, users can have an army of them guarding every potential weak spot in their pump systems.

The significance of edge processing in monitoring systems

Edge processing acts like the smart reflexes of monitoring systems. By processing data right where it is collected, there is no lag time and no need for the data to travel to a central nervous system before making a decision.

This means the monitoring system can react instantly to anomalies, triggering swift, localized responses that can potentially stop faults in their tracks. Edge processing keeps data flowing smoothly and intelligently, ensuring not a tremor of trouble slips through unnoticed.

24/7 visibility of pump health through continuous monitoring

Continuous monitoring keeps users’ eyes on the prize: uninterrupted operation. It is the round-the-clock surveillance that gives users peace of mind that Big Brother would envy. Pumps wear capes in modern industry and giving them 24/7 visibility means users can swoop in at the first sign of distress. The magic in continuous monitoring is in its relentless vigilance, offering a never-blinking gaze that catches issues whenever they dare to surface. It means getting ahead of problems that used to play hide-and-seek and maintaining performance at its peak.

Utilizing Data & Analytics for Intelligent Pump Maintenance

Harnessing the power of data and analytics transforms pump maintenance from a guessing game into a science. This is not just number crunching for the sake of it—this is about turning streams of data into a fountain of knowledge.

Using algorithms and deploying them in operation

Algorithms are the secret sauce in a maintenance strategy. They make sense of the jumble of data, picking out what is important and what is just noise. These smart math-based tools can predict which pump part might call it quits next or when to schedule a check-up—all with a level of precision that is like a laser-guided system for maintenance operations. Deploying algorithms means always being one step ahead. Once an anomaly is detected, an alert is generated, allowing users precious time to prevent the impending downtime.

Interpreting monitoring data and diagnostic testing

Diagnostic testing is the magnetic resonance imaging (MRI) for pumps. It gets down to the foundation of internals without needing to take anything apart. But getting the data is only half the battle. It is the interpretation that turns it into actionable insights. This is where experience waltzes with technology, crafting a maintenance plan that is both informed and intuitive. With this, every monitoring signal, each temperature readout and every vibration pattern becomes a meaningful cue to optimal pump health and function.

Key Takeaways

Smart maintenance: Predictive maintenance reshapes the approach to pump care, turning maintenance schedules from calendar-based to condition-based with the help of smart sensors.

Early detection: Catching anomalies through continuous, real-time monitoring with advanced edge processing is critical to preventing pump failures and expensive downtime.

Advanced analytics: Data-driven strategies facilitated by anomaly-detecting algorithms and practiced interpretation of diagnostics are key for intelligent pump maintenance.

Strategic implementation: Transitioning to modern monitoring tools paves the way for implementing effective condition monitoring across operations.

Inspiring confidence: Success stories highlight the value of predictive maintenance in avoiding unplanned downtime, while adaptation to new failure modes ensures ongoing operational resilience.

FAQs of Predictive Maintenance of Pumps With Condition Monitoring

What makes condition monitoring essential in predictive maintenance strategies?

Condition monitoring is essential in predictive maintenance strategies because it acts as a continuous health check for equipment, identifying issues early. This allows for planned repairs before failures happen and for maintenance schedules to be optimized based on real needs instead of guesswork. This approach saves time and money and enhances efficiency and extends the life span of equipment.

How can real-time data analysis extend pump life span and efficiency?

Real-time data analysis extends pump life span and efficiency by continuously monitoring pump performance and identifying potential issues early. This allows for timely interventions to prevent minor problems from escalating into major ones, reducing wear and tear and keeping pumps operating at optimal levels. Consequently, this proactive approach leads to longer pump life and enhanced operational efficiency.

Which industries benefit most from predictive maintenance of pumps?

Industries that benefit most from predictive maintenance of pumps include water treatment and municipal services, oil and gas, power generation, manufacturing, medical facilities, pharmaceuticals and food processing. These sectors depend heavily on the continuous operation of pumps for their daily activities, where interruptions can lead to significant costs, production losses and safety risks. Predictive maintenance serves as a crucial safeguard, ensuring that pumps remain operational, thereby maintaining industry efficiency and safety.