Fouling of equipment is one of the major costs of food processing. It requires cleaning, reducing production output and increasing chemical, energy and water consumption.

It is also linked with a broad set of product quality issues. This article will explain a method applied to steam injectors and other cases where there is burnt fouling—both to improve cleaning and, even more importantly, to prevent fouling formation.

Direct steam injection has long been a method of choice in the food industry, for cooking as well as high-temperature treatment for preservation of the end product. It is flexible and reactive—the temperature of the media can be adjusted in a matter of seconds.

Fouling in Steam Injectors

While injecting steam to a product, the challenge is ensuring an optimal mixing between them. Manufacturers have attempted many design efforts to make this happen, but it is impossible to completely prevent the direct contact of hot steam and product.

When hot steam and product meet, Maillard reaction (a nonenzymatic reaction between sugars and proteins that occurs upon heating and produces browning of some foods) and caramelization occur and reduce product quality.

As a result, small, burnt food particles migrate toward the side of the steam injector and holder tube downstream, where they create burnt fouling layers. In addition, when the product has a high viscosity and the steam is injected unevenly, steam bubbles will travel inside the heated media and burn the product in different locations inside the equipment or pipe.

The most common quality issue occurs when this burnt fouling accumulates, cracks and falls into the end product. Burnt fouling will be found as hard, black charcoal-like particles of various sizes in a typically lighter and smoother product, and therefore be considered a foreign body by end users.

This product contamination issue has several expensive consequences for food processors:

They face product recalls, customer complaints and impact to brand image.

They make a substantial investment in quality control (visual checks, sensors, etc.) without a possibility to detect 100 percent of the issues.

They have to regularly clean the steam injector with clean-in-place (CIP), limiting production time.

They use costly and heavily polluting chemical additives to achieve satisfactory cleaning results, considering burnt food residues are among the hardest fouling to clean by CIP.

Getting Rid of the Fouling Issue

Solving a fouling case in steam injectors has its challenges. The most common approach to cleaning is to stop the process and use mechanical water pressure and/or CIP, with a frequency that goes from daily to once every few weeks depending on the product and process conditions.

On the other hand, power ultrasound is known for its cleaning properties, removal of mineral and organic fouling from metal surfaces in cleaning baths. By combining calculating power and the right mechanical coupling and frequency, it is possible to apply software-guided power ultrasound inside process pipes—such as in the most fouled sections of a steam injector.

Before performing both cases explained here, the hypotheses were that if used during CIP, power ultrasound could help remove burnt fouling without the use of expensive chemical additives, and CIP time could be shortened. If used in conjunction with heat treatment, fouling deposits could be prevented. Consequently, it provides the possibility to remove product contamination from black particles and significantly lengthen production run.

Case Study No. 1

Improving Cleaning Performance

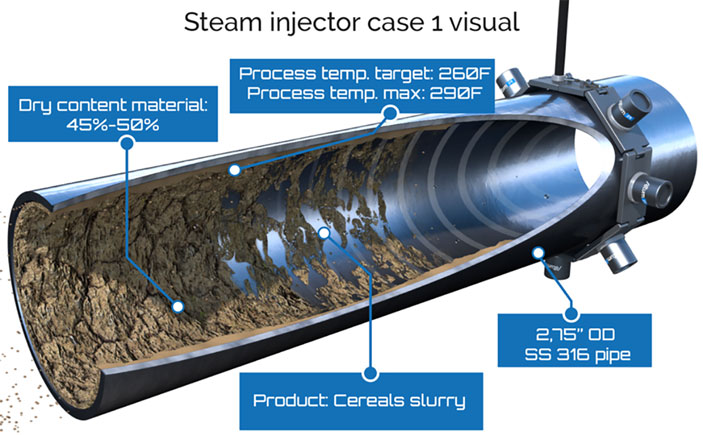

The first project occurred in spring 2019 in a European cereal slurry processor. Hot steam was pushed into a product containing 45 percent dry material—a mix of different cereal flour and sugar—with a target temperature of 260 F. The total length of the hot product pipe was 50 feet.

The absence of a nozzle and high viscosity caused severe and random product burn-on and contamination, forcing the plant to run CIP every seven days. CIP without an additive did not clean the pipe in a satisfactory manner and burnt fouling remained. High-power ultrasound of a specific frequency was applied externally via a mechanical attachment to maximize homogenous propagation of sonic waves in the pipe’s inner wall.

When used during CIP, ultrasound removed burnt product residues, forming an inhomogeneous hard layer of 0.02 inches to 0.05 inches of fouling inside the length of the pipe. Also, ultrasound removed fouling within minutes.

The project showed two benefits:

CIP time can be shortened from 50 minutes to 30 minutes.

Chemical additives, used at 3 percent concentration in caustic, can be quickly reduced to 0.5 percent.

.jpg)

Case Study No. 2

Fouling During Heat Treatment

Following the success in increasing CIP performance and reducing costs, another project was performed with the aim to gradually lengthen production runs and eliminate CIP from regular routine.

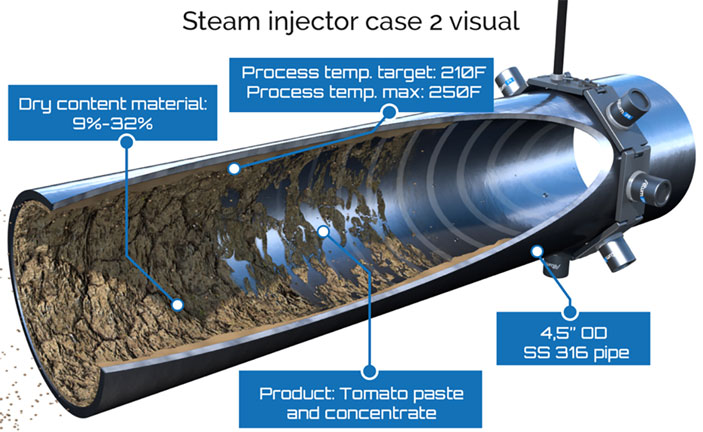

The project was performed in an American tomato processing plant over the production season in the summer of 2019. Hot steam was injected by nozzles into the media, going from crushed tomatoes to tomato concentrate (up to 32 percent dry material) and heated at 210 F.

CIP was done every seven to 10 days with a goal of avoiding a thick agglomeration of burnt-food residues that could pollute product.

Before the project, fouling was observed in two main locations: in the steam injection tube, mostly within a few inches of the nozzles, and in the bends following the steam injection tube, probably caused by burnt tomato particles transported downstream that stick to the metal pipe due to their hydrophobic properties.

The steam injection pipe (15 feet long, 4.5 inches in diameter) was treated by externally by applying high-power ultrasound to it over the entire production season. The pipe was opened before CIP to compare its cleanliness to a normal situation without high-power ultrasound. All openings confirm that the interior of the pipe remained clean when treated by power ultrasound. The longest production run achieved was 34 days.

Results

Contamination by burnt particles has been eliminated—there is no detection by the processor’s quality control and no end user complaints. The aim is to maintain that performance level even in absence of CIP.

The results show that software-guided power ultrasound can transform the fouling management approach during heat treatment in food production. It offers a promising path to prevent fouling from forming and sticking to pipes and heat exchangers. As shown in the steam injector cases presented, ultrasound may perform even better when coupled with hard and hot processing conditions that typically mean more denaturation of product by burning.