Know the importance of submergence to avoid spectra and time waveform hydraulic anomalies.

ProPump Services

03/26/2019

Major pharmaceutical manufacturers use chillers to maintain the temperature in the laboratories and production facilities throughout their campuses. The loss of the ability to maintain optimal temperatures within these facilities, especially laboratories, can mean the difference between a successful production run or millions in lost revenue, not to mention the impact on new pharmaceutical discoveries, or equipment failures and delays.

Image 1. The subject pumps are driven by 200-horsepower induction motors. (Images courtesy of ProPump Services)

Image 1. The subject pumps are driven by 200-horsepower induction motors. (Images courtesy of ProPump Services)Suction Piping

The suction inlet source is a common channel between two cooling towers. The suction inlet to each pump is a 20-inch pipe with a scalloped opening at the 6 o’clock position running perpendicular across the channel (Image 2). Image 2. Pump No. 15 is the first pump to the right, and No. 18 is the last pump to the left. The suction inlet to each pump is a 20-inch pipe with a scalloped opening running perpendicular across the channel. (Images courtesy of ProPump Services)

Image 2. Pump No. 15 is the first pump to the right, and No. 18 is the last pump to the left. The suction inlet to each pump is a 20-inch pipe with a scalloped opening running perpendicular across the channel. (Images courtesy of ProPump Services)Investigation

The investigation began with determining the existing hydraulic and mechanical condition of the subject pumps. The pumps were tested individually, then in parallel with each other. Pump design reviews, review of maintenance and operational historical records, and measurements of each pump and motor operating parameters included:- discharge flow (gallons per minute)

- suction and discharge pressures (pounds per square inch gauge)

- temperatures (degrees Fahrenheit)

- pump speed (rate per minute)

- motor current and voltage (volts of alternating current, amps)

- vibration signatures

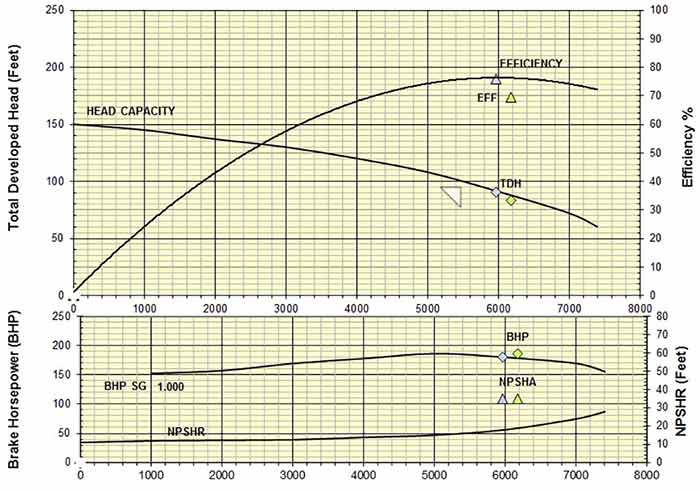

Image 3. Both pumps were operating at or near expected levels and with sufficient NPSHa.

Image 3. Both pumps were operating at or near expected levels and with sufficient NPSHa. Image 4. The spectrum presented reveals a significantly raised noise floor and random impacting in the time waveform, both indicative of hydraulic instability.

Image 4. The spectrum presented reveals a significantly raised noise floor and random impacting in the time waveform, both indicative of hydraulic instability.Technical Discussion of NPSHa, NPSHr & Submergence

NPSHa is defined as the total suction head in feet of liquid (absolute at the pump centerline) less the vapor pressure. Net positive suction head required (NPSHr) is determined by the pump manufacturer and is a function of several factors, including impeller eye design, flow, shaft speed, etc. For all operating conditions, the NPSHa must exceed the NPSHr. Submergence is the minimum intake or suction depth required to prevent surface and subsurface vortices, excessive flow re-whirl and more. For these installations the NPSHa to NPSHr was deemed adequate and within the acceptable margin of 10 to 35 percent. However, submergence is inadequate and surface vortexing was observed at the inlet to pump No. 18, as shown in Image 5. Vortexing allows air ingestion into the impeller eye and resultant cavitation. Image 5. Submergence is inadequate and surface vortexing was observed at the inlet to pump No. 18.

Image 5. Submergence is inadequate and surface vortexing was observed at the inlet to pump No. 18.