When it comes to pumping, there are a variety of technologies available to get the job done. One such technology is the progressive cavity (PC) pump. This pump is part of the positive displacement pump family. Its identifying features are the rotor and stator. Together, the rotor and stator create sealed cavities that progress through the pump, moving a defined volume of fluid with each revolution.

This article will dive into the basics of the technology, outline common applications and industries, and discuss how progressive cavity pumps can improve the efficiencies of plant operations and help users achieve low total cost of ownership.

What Is a Progressive Cavity Pump?

A progressive cavity pump, also known as an eccentric screw pump, PC pump or cavity pump, is a type of rotary positive displacement pump. Found in a spectrum of industries from food processing to mining, the progressive cavity pump is desired due to its unique design and capability to handle viscous, aggressive, abrasive and shear-sensitive fluids.

The technology behind PC pumps is the rotor and stator that work together to transfer fluid via a series of cavities as the rotor turns within the stator. This design allows for a consistent flow rate proportional to the rate of rotation. The large cavities also allow for shear-sensitive products to be pumped without degradation. Since the cavities are sealed and there are no clearances in the pumping element, the fluid is gently transferred within the cavity with exceptionally low shear. This is especially important when the conveyed product can be damaged by shear caused by pumps with internal clearances, like gear or rotary lobe pumps.

How Does a Progressive Cavity Pump Work?

The rotor-stator interaction

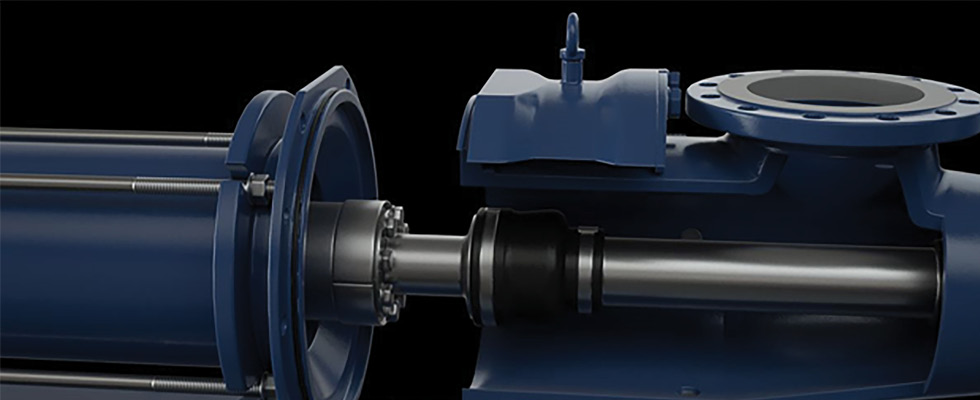

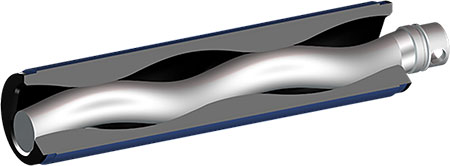

At the core of a progressive cavity pump is the rotor-stator interaction. The rotor, a precision-engineered single-helix metal component, is designed for an interference fit within the stator’s double-helix cavity. The stator, typically constructed from a durable elastomer, conforms to the rotor’s shape, creating a series of cavities that maintain their size and shape throughout the pumping process.

Fluid movement and sealed cavities

As the rotor turns, it forms tightly sealed cavities that trap the fluid. These cavities then progress from the pump’s inlet to its discharge port, ensuring a consistent and controlled flow. This unique mechanism allows the progressive cavity pump to handle a wide range of fluid viscosities and compositions, from water to thick sludges, without altering the fluid’s integrity.

Low shear and pulsation

One of the standout features of progressive cavity pumps is their low-shear operation. The gentle movement of the rotor minimizes the shearing forces applied to the fluid, making these pumps ideal for shear-sensitive materials like food products—yogurt, for example—or delicate chemical mixtures like polymer solutions.

Consistent flow and efficiency

Regardless of the fluid’s viscosity, progressive cavity pumps deliver a constant flow rate due to the sealed cavity with a defined volume. This consistent performance, coupled with the pump’s high volumetric efficiency, makes it a preferred choice for applications requiring precise fluid handling and metering. Accuracies of +/- 0.05% can be achieved coupled with a variable frequency drive with feedback from a flowmeter.

Advantages of Progressive Cavity Pumps

Progressive cavity pumps offer numerous benefits, including:

High efficiency and reliability: Efficient and consistent performance, which reduces the risk of equipment failure and production disruptions

Low shear: Gently handles shear-sensitive materials such as food products or adhesives

Smooth flow: Delivers a virtually pulse-free flow, perfect for metering and dosing applications

Versatility: Capable of pumping a variety of fluids, from water to highly viscous, non-flowing products

Simplicity of operation: Straightforward design with single rotating unit and no internal clearances, making them easy to install, operate and maintain; saves time and money while ensuring reliable performance

Ability to handle challenging fluids: Effectively moves a wide range of fluids, including those with high viscosity or containing solids, ensuring suitability for a broad spectrum of applications

No valves or reciprocating parts: Nothing to clog or gas lock, enhancing the pump’s durability

Good resistance to abrasion: Suitable for the toughest of applications with fluid containing abrasive particles

High suction lift capabilities: Self-priming characteristics make it possible to handle suction lifts up to 9 meters (m)/29.5 feet (ft)

Progressive Cavity Pumps Applications

Progressive cavity pumps are highly adaptable. Due to their ability to handle a variety of challenging fluids, they are suitable for applications across a broad range of industries, such as:

Environmental engineering:

Wastewater treatment

Drinking water treatment

Biogas/anaerobic digestion

Mining and mineral processing

Food and beverage:

Dairy industry

Dough processing and bakeries

Fruit and vegetable processing

Poultry and meat processing

Fishing industry

Fruit and vegetable juice production

Brewing industry and distilleries

Wine and cider making

Sugar industry

Food waste

Oil and gas:

Upstream exploration and production

Downstream applications

Chemical and biochemicals

Petrochemicals

Oil production

Offshore

Bioethanol and biodiesel

Additional applications:

Pharmaceutical and cosmetics

Pulp and paper

Agriculture

Other industries

Selecting the Right Progressive Cavity Pump

When selecting a progressive cavity pump, it is important to consider factors such as fluid characteristics, flow rate, pressure requirements and installation environment.

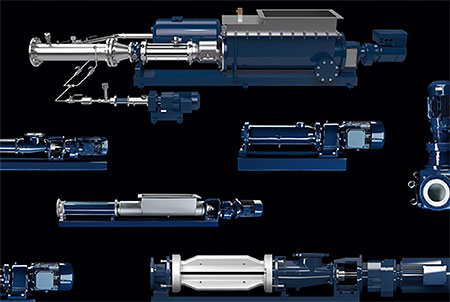

Custom solutions for diverse industries

Progressive cavity pumps can be engineered to address the requirements from a wide range of industries, including wastewater treatment, food and beverage, oil and gas and chemical processing. Custom solutions are often available that can handle everything from high-viscosity fluids to aggressive chemicals, ensuring end users receive a pump that fits their specific needs.

Maintenance and after-sales support

Regular maintenance is crucial to ensure the longevity and optimal performance of a progressive cavity pump. This includes:

Routine inspections: Check for wear and tear on the rotor and stator.

Lubrication: Ensure proper lubrication of moving parts to prevent premature wear.

Mechanical seal inspection: Timely inspection of seals can help prevent leaks.

Progressive cavity pumps have been around since the early 1930s and will continue to be part of pumping solutions found in a variety of applications around the globe for years to come.

This article has reviewed the basic concepts of progressive cavity pumps, the applications they are found in and their advantages. The next article in this two-part series will take a deeper, more technical look into progressive cavity pumps.

Demanding applications and the increasing availability of technology have allowed the industry to adapt the basic progressive cavity pump design for use in the most extreme applications. Part 2 of this series will cover concepts and designs for handling products with little to no flowability and, in the new era, digital pump monitoring.