As the name indicates, the purpose of a pulsation dampener is to level out pressure fluctuations in the system. These devices come in various designs, but they all serve the purpose of absorbing and releasing volume to limit pressure pulsations or fluctuations. Typically, designs are bladder, diaphragm and piston types, but they can also include simple flexible hoses, standpipes and other methods.

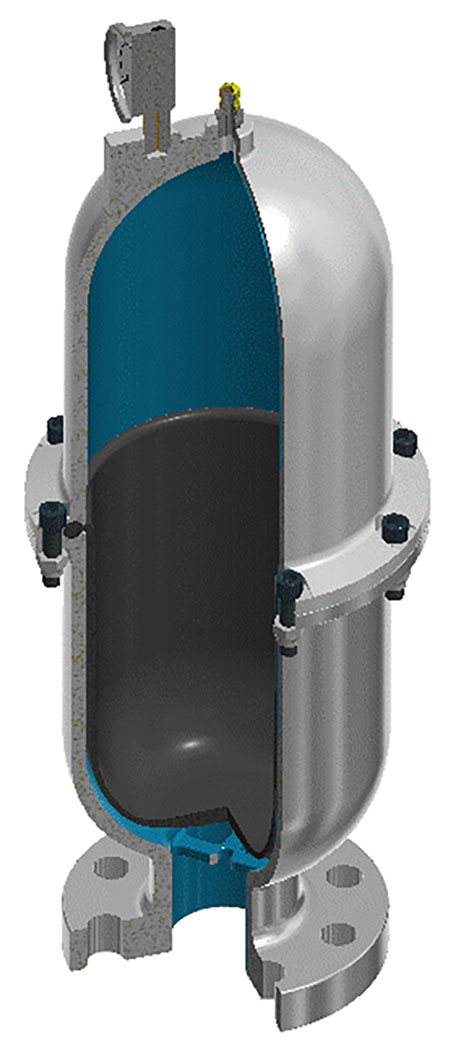

Reciprocating and certain rotary positive displacement pumps will induce pressure pulsations because their flow rate is not steady. Pressure pulsations can result in noise and pipe shaking and may also damage instrumentation and cause cavitation at the inlet of the pump. In pumping systems, dampeners may be used on the discharge (outlet) of the pump as pulsation dampeners or on the suction (inlet) of the pump to stabilize the suction pressure. Additionally, when sized and charged appropriately, these devices can be used to mitigate water hammer (surge) and thermal expansion or may be used as accumulators in combination with pressure control. Image 1 illustrates a bladder-style dampener. Note that there is a pressure gauge on the top with a port to precharge it. The precharge is typically less than the maximum pressure fluctuation so the bladder can expand into the area that is precharged to absorb excess volume and then release volume back into the system.

For additional information on pump system pressure pulsations and water hammer (surge) as well as methods to manage, understand and mitigate issues, visit Hydraulic Institute University at training.pumps.org for live and on-demand training options.

For more HI Pump FAQs, click here.