There are many items to consider in the design of a pump used for high-temperature liquids, and relevant standards and the pump manufacturer should be consulted and provided all the required application information. From a standards perspective, the Hydraulic Institute’s ANSI/HI 14.3 Rotodynamic Pumps for Design & Application provides general design considerations, and the American Petroleum Institute’s (API’s) published API 610 Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries provides minimum design requirements for pumps used in the stated industries, which often include elevated liquid temperatures.

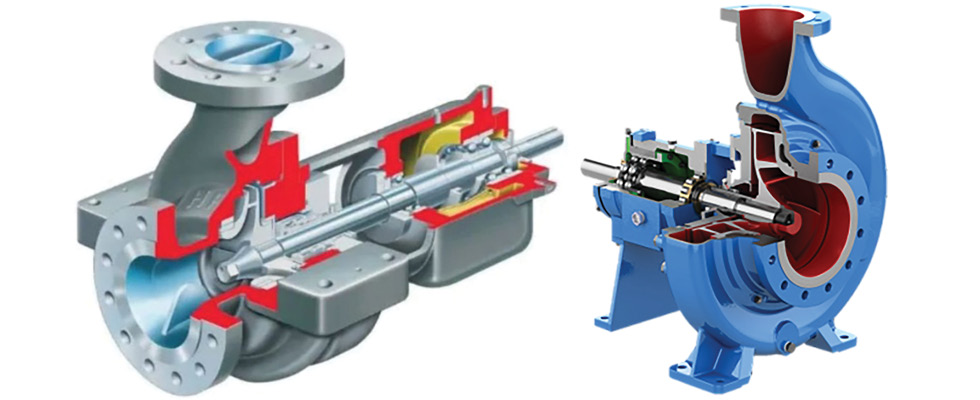

A common design feature often noticed on high-temperature pump applications is a centerline-mounted pump casing. Within the standard nomenclature, these are OH2 types for overhung pumps and BB2, BB3, BB4 and BB5 for between bearing pumps. The centerline-mounted pump casing allows for even thermal expansion, which limits the effect of thermal expansion on coupling misalignment and clearances between stationary and rotating parts.

In addition to the standards previously cited, the American Society of Mechanical Engineers (ASME) has published ASME B73.1 Specification for Horizontal End Suction Centrifugal Pumps for Chemical Process. Note that ASME B73.1 is focused on standardizing foot-mounted (OH1) pump types, which are not ideal for high temperatures. However, within the specification, it states, “Pumps should be available for temperatures up to 500 F.” It provides guidance that other modifications may be required and also advises that for services above 350 F, centerline mounting and oil sump cooling should be made available.

For additional information, visit Hydraulic Institute University at training.pumps.org to review the new industry certification, Pump System Certification (PSC) Level 1, and the associated training and certification exam preparation materials.