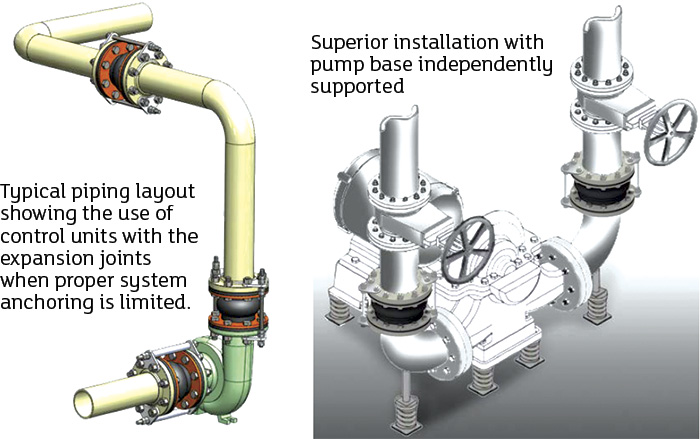

The Sealing Sense column on expansion joints fundamentals in the January 2017 issue of Pumps & Systems (Read it here) concluded the five-part “Back to Basics” series presented by the Fluid Sealing Association (FSA). This month’s column focuses on a new technical resource that thoroughly explains the performance, design and variations of expansion joints. The Piping Expansion Joint Division recently completed revisions for the 8th edition of the Piping Handbook, now called the Piping Expansion Joints Technical Handbook. The revised handbook includes a contemporary format with new three-dimensional graphics (see Figure 1). The technical content has been expanded and revised to reflect a wider variety of expansion joints and to make the handbook more relevant to the user.

Figure 1. New graphics in the handbook to illustrate expansion joint usage (Graphics courtesy of the author)

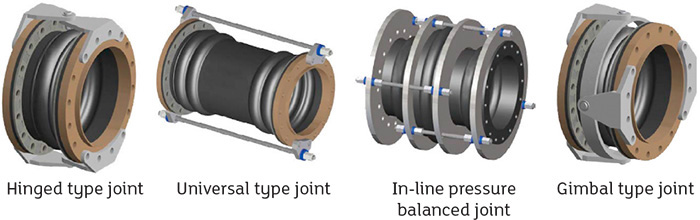

Figure 1. New graphics in the handbook to illustrate expansion joint usage (Graphics courtesy of the author) Figure 2. Expansion joint types

Figure 2. Expansion joint types- Hinged joints: Hinged type rubber expansion joints are designed to permit angular rotation in one plane. The arrangement consists of a pair of hinge plates connected with pins and attached to the expansion joints’ external or internal hardware.

- Universal joints: Universal type rubber expansion joints are designed to permit extension, compression, lateral and angular movements. The arrangement consists of two rubber expansion joints connected by a center spool with restraint hardware.

- Pressure balanced: Pressure balanced type rubber expansion joints are designed to absorb compression, as well as lateral and angular movements, while restraining the pressure thrust force. The arrangement consists of two or three rubber expansion joints and interconnecting hardware.

- Gimbal joints: Gimbal type rubber expansion joints are designed to permit angular rotation in multiple planes. The arrangement consists of two pairs of hinge plates connected with pins to a common gimbal ring and attached to the expansion joints’ external or internal hardware.

- FSA-PSJ-701-06 Non-Metallic Expansion Joint Hydrotesting and Vacuum Testing: This standard covers the hydro testing and vacuum testing of non-metallic flanged expansion joints. The purpose of the testing is to verify that the expansion joint meets a standard performance or a customer-specified performance.

- FSA-PSJ-702-15 Rubber Flanged Non-Metallic Expansion Joint Installation, Maintenance, and Storage: This specification covers the installation, maintenance and storage of rubber flanged non-metallic expansion joints. The purpose of the standard is to ensure the proper handling of expansion joints. The bolt torque values listed in this standard were updated after review and verification.

- FSA-PSJ-703-11 Guidelines for Elastomers Used in Piping Systems Non-Metallic Piping Joints: This guideline provides the typical properties of elastomers most frequently used for tube and cover compounds in the manufacture of piping expansion joints for a wide range of applications.